QR Code Stickers Australia

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

Vinyl stickers have revolutionized how Australian businesses and individuals express themselves, promote their brands, and organize their lives. From the scorching heat of Western Australia’s outback to the humid coastal regions of Queensland, vinyl stickers must withstand some of the world’s most challenging environmental conditions while maintaining their vibrant appearance and strong adhesion.

Whether you’re a business owner looking to create eye-catching promotional materials, a tradesperson needing durable equipment labels, or someone wanting to personalize your belongings, understanding vinyl sticker materials, applications, and durability factors is crucial for making informed decisions that deliver long-lasting results.

This comprehensive guide will walk you through everything you need to know about vinyl stickers in the Australian context, helping you choose the right materials, understand their applications, and ensure maximum durability in our unique climate conditions. Building on FastStickers’ expertise in creating comprehensive educational resources, this guide serves as your definitive resource for vinyl sticker success across Australia.

At their core, vinyl stickers are adhesive labels manufactured from polyvinyl chloride (PVC), a synthetic plastic polymer renowned for its exceptional durability and versatility. Unlike traditional paper stickers that quickly succumb to Australia’s harsh environmental conditions, vinyl stickers are engineered to withstand extreme temperatures, intense UV radiation, moisture exposure, and mechanical stress while maintaining their visual appeal and adhesive integrity.

The superiority of vinyl stickers becomes immediately apparent when you consider Australia’s unique challenges. Paper stickers might last weeks or months in our climate, but quality vinyl stickers can perform reliably for years, making them the economically sensible choice for any application requiring longevity. The technical composition of vinyl materials creates a barrier against water penetration, UV degradation, and thermal expansion that would quickly destroy alternative materials.

The evolution of vinyl sticker technology over the past three decades has been remarkable. Early vinyl formulations were rigid and prone to cracking, but modern manufacturing processes create flexible, conformable materials that adapt to curved surfaces while maintaining their protective properties. Advanced plasticizers and stabilizers now allow vinyl stickers to remain pliable across temperature ranges from -40°C to +80°C, ensuring reliable performance whether they’re applied to refrigerated transport vehicles in Melbourne’s winter or mining equipment in the Pilbara’s summer heat.

From an economic perspective, vinyl stickers deliver exceptional value through their extended lifespan and reduced replacement frequency. A business investing in quality vinyl signage today can expect 5-7 years of reliable performance, compared to 6-12 months for paper alternatives. This longevity translates directly into cost savings, reduced maintenance time, and consistent brand presentation that builds customer trust and recognition.

The manufacturing process itself contributes to vinyl’s superior performance characteristics. During production, PVC resin is heated, mixed with stabilizers and colorants, then calendared or cast into precise thicknesses. This controlled process creates uniform material density and consistent adhesive application, ensuring every sticker meets professional quality standards. Quality control measures include testing for adhesion strength, color stability, and environmental resistance before products reach Australian customers.

For Australian applications specifically, vinyl stickers offer unmatched resistance to our continent’s extreme conditions. The material’s molecular structure resists moisture absorption that causes warping and delamination, while UV stabilizers prevent the color fading that plagues inferior materials. Whether you’re labeling equipment in Darwin’s tropical humidity or creating signage for Alice Springs’ desert environment, vinyl stickers maintain their appearance and functionality where other materials simply fail.

Now that we understand what makes vinyl stickers special, let’s explore the different types of vinyl materials and how they’re engineered for specific applications.

The world of vinyl sticker materials is far more sophisticated than many realize, with distinct manufacturing processes creating materials optimized for specific performance requirements. Understanding these differences empowers you to make informed decisions that ensure optimal results for your particular application and environmental conditions.

Cast versus Calendared Vinyl: The Foundation of Performance

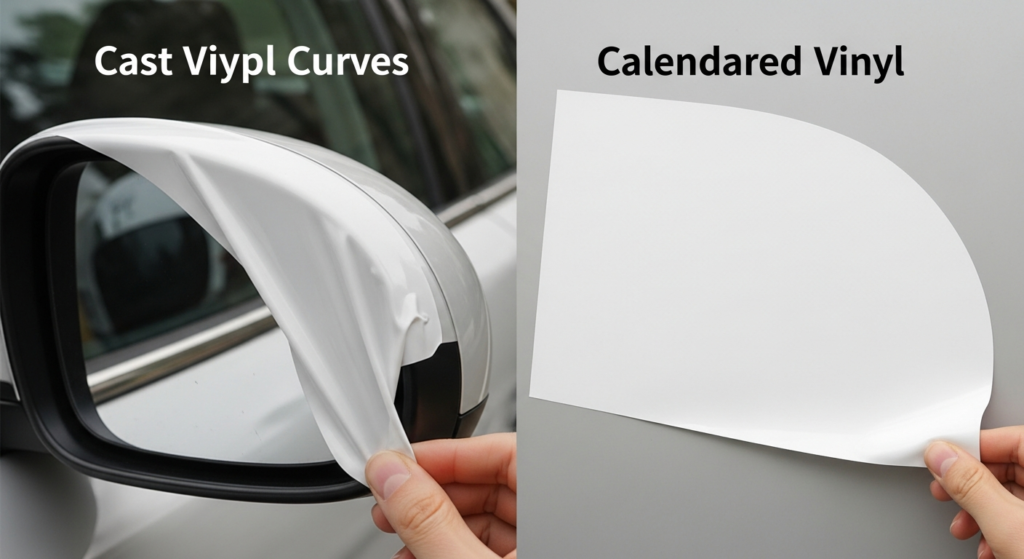

The fundamental distinction in vinyl materials lies in their manufacturing method, which dramatically affects performance characteristics, longevity, and cost. Cast vinyl represents the premium tier, created through a process where liquid PVC is poured onto a release liner and allowed to cure naturally. This method produces a thin, highly conformable material with excellent dimensional stability and superior durability. Cast vinyl molecules align randomly during curing, creating internal stress patterns that resist shrinkage and maintain adhesion even as materials age.

Calendared vinyl, by contrast, is manufactured by pressing heated PVC through a series of rollers, creating a thicker, more economical material. While calendared vinyl costs significantly less than cast alternatives, the rolling process creates molecular alignment that can lead to shrinkage over time, particularly in high-temperature environments common across Australia. The molecular memory inherent in calendared vinyl means it constantly tries to return to its original flat state, which can cause edge lifting and adhesive failure on curved or textured surfaces.

For Australian applications, the choice between cast and calendared vinyl often depends on project duration and surface complexity. Cast vinyl excels in demanding applications like vehicle graphics, outdoor signage, and curved surface applications where its conformability and stability justify the higher cost. Calendared vinyl works well for short-term indoor applications, flat surface labeling, and budget-conscious projects where its limitations won’t impact performance.

Adhesive Technologies: Matching Bond Strength to Application Requirements

The adhesive component of vinyl stickers is equally critical, with different formulations designed for specific surface types, removal requirements, and environmental conditions. Understanding these options prevents costly mistakes and ensures optimal performance across diverse Australian applications.

Removable adhesives utilize lower tack formulations that create sufficient bond strength for temporary applications while allowing clean removal without surface damage. These adhesives work particularly well on painted surfaces, glass, and finished metal where permanent bonding isn’t required. Removable stickers from FastStickers utilize specially formulated adhesives that maintain removability even after extended exposure to Australian heat and UV radiation.

Permanent adhesives create chemical bonds with surface materials that strengthen over time, making removal difficult or impossible without surface damage. These formulations excel in asset labeling, safety signage, and branding applications where tamper resistance and longevity are priorities. The adhesive chemistry continues evolving after application, reaching maximum bond strength within 24-48 hours under normal conditions.

High-tack adhesives represent specialized formulations designed for challenging surfaces like powder-coated metals, textured plastics, and low-surface-energy materials. These aggressive adhesives penetrate surface irregularities and create mechanical bonds that standard adhesives cannot achieve. High-tack formulations prove invaluable for industrial applications, outdoor equipment labeling, and surfaces that resist conventional adhesive bonding.

Finish Options and Performance Characteristics

Surface finish significantly impacts both aesthetic appeal and functional performance of vinyl stickers. Gloss finishes provide vibrant color reproduction and easy cleaning but show fingerprints and scratches more readily than alternatives. The smooth surface facilitates ink adhesion during printing while reflecting light uniformly for maximum visual impact.

Matte finishes reduce glare and provide sophisticated appearance while hiding minor surface imperfections and fingerprints. The textured surface scatters light diffusely, creating a premium appearance that works particularly well for interior applications and high-end branding. Matte vinyl often costs slightly more than gloss alternatives but delivers superior performance in applications where reflection control matters.

Specialty finishes including brushed metal effects, wood grains, and carbon fiber textures create unique aesthetic possibilities while maintaining vinyl’s practical advantages. These decorative options allow creative flexibility without sacrificing the durability and weather resistance that make vinyl stickers superior to alternatives.

Thickness Considerations and Conformability

Vinyl thickness directly affects conformability, with thinner materials adapting more readily to curved surfaces and complex geometries. Standard vinyl ranges from 2-6 mils thickness, with thinner options providing superior conformability for vehicle graphics and curved applications. Thicker vinyl offers enhanced durability and puncture resistance but requires more aggressive heating and pressure for complex surface conforming.

The relationship between thickness and performance creates trade-offs that must be considered for each application. Thin, conformable vinyl might stretch and distort during installation on highly curved surfaces, while thick, durable vinyl might not conform adequately to surface details. Professional installers balance these factors based on surface geometry, expected lifespan, and aesthetic requirements.

Color stability represents another critical performance factor affected by material formulation. UV stabilizers and pigment selection determine how well vinyl maintains its original appearance under Australia’s intense solar radiation. Premium vinyl formulations utilize light-fast pigments and advanced stabilizer packages that prevent color shifting and fading for years under extreme UV exposure.

With a solid understanding of materials and adhesives, let’s explore the diverse applications where these different vinyl types excel across Australian industries and personal uses.

The versatility of vinyl stickers becomes apparent when examining their widespread adoption across diverse Australian industries and applications. From multinational corporations to individual enthusiasts, vinyl stickers provide practical solutions that combine durability, aesthetic appeal, and economic value in ways that alternative materials simply cannot match.

Automotive and Transportation Applications

Australia’s automotive industry has embraced vinyl stickers for applications ranging from promotional graphics to functional labeling. Fleet managers across the continent rely on vinyl graphics to transform commercial vehicles into mobile advertisements that withstand highway speeds, weather extremes, and constant UV exposure. Bumper stickers represent one of the most recognizable applications, but the automotive sector’s vinyl usage extends far beyond promotional messaging.

Commercial transport companies use vinyl stickers for compliance labeling, vehicle identification, and safety messaging that must remain legible and securely attached throughout vehicle lifecycles. Mining companies operating in remote regions depend on vinyl labels to identify equipment, mark hazardous materials, and provide safety instructions that survive in environments where temperatures regularly exceed 50°C and dust exposure would quickly destroy paper alternatives.

The marine industry presents unique challenges that vinyl stickers meet effectively. Boat registration numbers, safety instructions, and decorative graphics must withstand saltwater exposure, UV radiation, and constant moisture while maintaining appearance and adhesion. Marine-grade vinyl formulations resist osmotic blistering and salt crystallization that would quickly damage inferior materials.

Vehicle customization represents a growing market where vinyl stickers enable personal expression without permanent modification. Enthusiasts use vinyl graphics to personalize motorcycles, cars, and recreational vehicles with designs that can be removed or updated as preferences change. The removable nature of quality vinyl allows customization flexibility while protecting underlying paint and surface finishes.

Commercial and Business Applications

Australian businesses have discovered vinyl stickers provide cost-effective solutions for branding, organization, and communication challenges. Retail environments use vinyl stickers for product labeling, promotional messaging, and wayfinding that must withstand constant handling and cleaning while maintaining professional appearance. The ability to print custom designs on demand allows businesses to respond quickly to marketing opportunities and seasonal promotions.

Manufacturing facilities rely on vinyl labels for asset tracking, safety identification, and workflow organization. Color-coded systems using vinyl stickers help workers quickly identify equipment status, safety protocols, and maintenance schedules in environments where clear communication prevents accidents and improves efficiency. The chemical resistance of quality vinyl ensures labels remain legible despite exposure to industrial cleaning agents and process chemicals.

Service industries from plumbing to electrical contracting use vinyl stickers for equipment identification, customer communication, and brand building. Professional-appearing labels reinforce competence and attention to detail that customers associate with quality workmanship. Weather-resistant properties ensure outdoor equipment labels remain professional-looking throughout service lifecycles.

Healthcare facilities utilize vinyl stickers for patient identification, equipment labeling, and safety communication where hygiene and durability requirements exceed what paper labels can provide. The smooth surface of vinyl stickers facilitates cleaning and disinfection while maintaining adhesion and legibility under constant sanitization protocols.

Personal and Recreational Uses

Individual Australians have embraced vinyl stickers for personal expression, organization, and hobby applications that showcase the material’s versatility beyond commercial uses. Laptop stickers have become ubiquitous among students and professionals who use vinyl graphics to personalize devices while protecting surfaces from scratches and wear. The removable nature of quality vinyl allows customization changes without damaging expensive electronics.

Water sports enthusiasts rely on vinyl stickers to label equipment, express personality, and provide identification that survives constant moisture exposure. Surfboard graphics, kayak labeling, and diving equipment identification must withstand saltwater immersion and UV exposure that would quickly destroy paper alternatives. Marine-grade vinyl formulations resist the osmotic pressure and salt crystallization that challenge adhesive bonds in aquatic environments.

Home organization has benefited significantly from vinyl sticker applications. Kitchen labeling, storage identification, and decorative accents use vinyl’s durability and easy application to create functional solutions that maintain appearance despite daily use and cleaning. The variety of colors, finishes, and cutting options allows homeowners to create coordinated organizational systems that combine functionality with aesthetic appeal.

Hobby and craft applications demonstrate vinyl’s precision and versatility. Model builders use vinyl stickers for scale details that achieve realism impossible with paint alone. The precise cutting capabilities of modern vinyl plotting technology enable intricate designs and lettering that enhance hobby projects while providing durability that preserves craftsmanship investments.

Industrial and Trade Applications

Australian industrial sectors depend on vinyl stickers for applications where failure isn’t merely inconvenient—it’s potentially dangerous. Mining operations use vinyl labels for hazardous material identification, equipment marking, and safety communication that must remain clearly visible despite dust, heat, and mechanical abuse. The chemical resistance of industrial-grade vinyl ensures critical safety information remains legible throughout equipment lifecycles.

Construction sites utilize vinyl stickers for tool identification, safety labeling, and project organization in environments where durability and weather resistance determine label effectiveness. Color-coded systems using vinyl stickers help workers quickly identify safety protocols, equipment status, and project phases while maintaining visibility despite exposure to weather, dust, and handling.

Agricultural applications showcase vinyl’s resistance to environmental extremes. Farm equipment labeling must survive UV exposure, chemical cleaning, and mechanical stress while remaining legible for safety and operational information. Livestock identification and facility labeling require durability that withstands weather exposure and animal interaction while maintaining readability for operational efficiency.

Manufacturing environments with specific requirements for chemical resistance, temperature tolerance, or cleanroom compatibility rely on specialized vinyl formulations that meet industry standards while providing reliable identification and communication. The ability to customize vinyl stickers for specific industrial requirements ensures optimal performance in demanding applications.

Event and Promotional Uses

The events industry has discovered vinyl stickers provide flexible, cost-effective solutions for temporary signage, promotional items, and crowd management. Popular applications across Australia include festival branding, conference identification, and promotional giveaways that create lasting brand impressions while demonstrating quality and attention to detail.

Temporary applications benefit from vinyl’s balance of adhesion strength and removability. Event signage must adhere securely during events while removing cleanly afterward without damaging surfaces. Removable vinyl formulations achieve this balance while maintaining professional appearance throughout event durations.

Promotional campaigns use vinyl stickers to create memorable brand interactions that recipients value and retain. Unlike disposable promotional items, quality vinyl stickers provide lasting utility while continuously reinforcing brand messaging. The perceived value of well-designed vinyl stickers exceeds their production cost, making them cost-effective promotional tools.

Understanding applications is just the beginning—now let’s examine how Australia’s unique climate conditions impact vinyl sticker performance and what you need to know for optimal durability.

Australia’s extreme environmental conditions present unique challenges that separate quality vinyl stickers from inferior alternatives. Understanding how our continent’s intense UV radiation, temperature extremes, and diverse climate zones affect vinyl performance enables informed material selection and realistic lifespan expectations for different applications and regions.

The UV Challenge: Australia’s Intense Solar Radiation

Australia experiences some of the world’s highest UV radiation levels, with the UV index regularly exceeding 10 across much of the continent during summer months. This intense solar energy breaks down molecular bonds in inferior materials, causing color fading, surface degradation, and adhesive failure that can destroy paper stickers within weeks of outdoor exposure.

Quality vinyl stickers combat UV damage through sophisticated stabilizer packages and light-fast pigments engineered specifically for high-radiation environments. UV stabilizers absorb harmful radiation before it can break polymer chains, while hindered amine light stabilizers (HALS) neutralize free radicals that would otherwise cascade through material structures causing widespread degradation.

The relationship between UV exposure and vinyl degradation follows predictable patterns that help establish realistic lifespan expectations. Research on vinyl durability indicates that premium vinyl formulations can withstand 5-7 years of direct Australian sun exposure while maintaining color integrity and adhesive performance. However, this lifespan varies significantly based on specific formulation quality, application surface, and regional UV intensity.

Color stability represents a critical performance indicator for outdoor vinyl applications. Certain pigments prove more susceptible to UV degradation than others, with red and yellow hues traditionally showing faster fading rates than blues and blacks. Modern UV-resistant pigment systems have largely overcome these limitations, but understanding color-specific performance characteristics helps set appropriate expectations for different design elements.

The cumulative nature of UV damage means vinyl degradation accelerates over time as stabilizer systems become depleted and material surfaces begin showing microscopic damage. Regular inspection and maintenance become increasingly important as vinyl stickers age, with early intervention potentially extending useful lifecycles significantly.

Temperature Extremes and Thermal Cycling Effects

Australian temperature variations challenge vinyl sticker performance through direct heating effects and thermal cycling stress. Desert regions regularly experience surface temperatures exceeding 70°C, while some mountain areas see winter temperatures below freezing. These extreme conditions test vinyl flexibility, adhesive bond strength, and dimensional stability in ways that temperate climate applications never experience.

High temperature exposure affects vinyl stickers through multiple mechanisms. Excessive heat can soften adhesive formulations, potentially causing flow and reduced bond strength. Material thermal expansion can create stress concentrations at edges and corners that lead to lifting and failure. Prolonged heat exposure can accelerate chemical reactions within vinyl formulations, potentially causing color shifts and surface texture changes.

Cold temperature exposure presents different challenges, particularly for adhesive performance. Low temperatures can embrittle adhesive formulations, reducing their ability to maintain bonds as materials undergo thermal contraction. The coefficient of thermal expansion differences between vinyl and substrate materials can create stress concentrations that challenge adhesive bonds during temperature cycling.

Thermal cycling—the repeated expansion and contraction caused by daily temperature variations—represents one of the most demanding conditions for vinyl sticker durability. Australian climate research indicates that thermal cycling stress can reduce vinyl lifespans by 20-30% compared to stable temperature conditions, making material selection particularly critical for applications experiencing wide temperature swings.

The molecular structure of vinyl materials determines their response to temperature variations. Plasticizers that maintain flexibility at low temperatures can potentially migrate out of materials at high temperatures, leading to gradual embrittlement over time. Quality vinyl formulations balance plasticizer chemistry to optimize performance across Australia’s extreme temperature range.

Regional Climate Variations and Material Performance

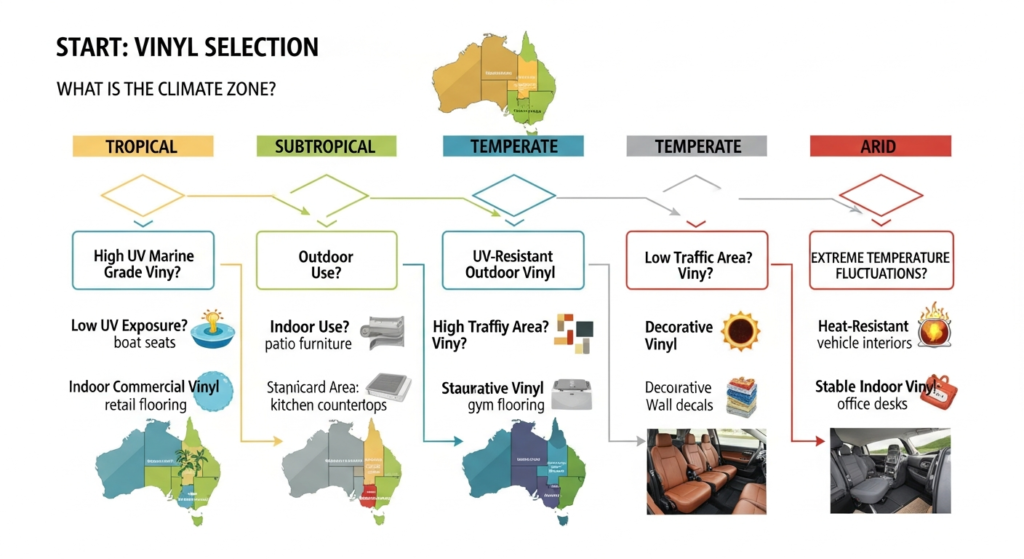

Australia’s diverse climate zones create distinctly different challenges for vinyl sticker performance, requiring regional considerations for optimal material selection and lifespan expectations. Understanding these variations enables informed decision-making that maximizes performance and value for specific applications.

Tropical northern regions experience consistently high humidity, intense UV radiation, and elevated temperatures that create aggressive degradation conditions. The combination of moisture and heat accelerates chemical reactions while UV intensity remains consistently high throughout most of the year. UV-resistant vinyl options prove essential for reliable performance in these demanding conditions.

Coastal environments present unique challenges through salt air exposure, high humidity, and consistent UV radiation. Salt crystallization can penetrate material structures and cause mechanical damage while accelerating corrosion of adhesive bonds. Marine-grade vinyl formulations with enhanced moisture resistance and salt tolerance prove necessary for reliable coastal performance.

Arid inland regions subject vinyl stickers to extreme temperature variations, intense UV exposure, and dust abrasion that tests material durability through multiple stress mechanisms. The low humidity reduces some degradation pathways but intensifies others, particularly UV damage and thermal stress. Premium vinyl formulations with robust stabilizer packages prove cost-effective for these demanding applications.

Temperate southern regions offer more moderate conditions but still present challenges through seasonal temperature variations and winter moisture exposure. These conditions favor longer vinyl lifespans but still require quality materials for optimal performance and professional appearance maintenance.

Seasonal Weather Patterns and Performance Impact

Australia’s seasonal weather patterns create predictable stress cycles that affect vinyl sticker performance and longevity. Understanding these patterns helps establish maintenance schedules and replacement timelines that prevent unexpected failures and maintain professional appearance.

Summer conditions typically represent peak stress periods for outdoor vinyl applications. The combination of maximum UV intensity, highest temperatures, and often reduced humidity creates aggressive degradation conditions that can rapidly age inferior materials. Regular inspection during summer months helps identify emerging problems before they become significant failures.

Winter conditions in many Australian regions introduce moisture challenges through increased rainfall and higher humidity levels. While UV intensity decreases, moisture exposure can test adhesive bond strength and potentially cause edge lifting if materials aren’t properly selected and applied. Weatherproof vinyl characteristics become particularly important during extended wet periods.

Transitional seasons often create thermal cycling stress as temperature variations reach their maximum ranges. Spring and autumn temperature swings can stress vinyl materials and adhesive bonds that have been conditioned by summer heat or winter moisture. Understanding these seasonal patterns helps predict when vinyl replacement might become necessary.

The cumulative effects of seasonal cycling mean vinyl degradation rates aren’t linear but often accelerate as materials age and protective systems become depleted. Quality tracking through inspection and maintenance records helps establish replacement schedules that maintain professional appearance while maximizing material lifecycles.

Knowing how climate affects your stickers leads us naturally to the essential maintenance practices that can significantly extend their lifespan in harsh Australian conditions.

Proper installation, routine care, and proactive maintenance dramatically extend vinyl sticker lifecycles while maintaining professional appearance throughout their service life. Understanding these best practices transforms vinyl stickers from consumable items into long-term investments that deliver exceptional value through extended performance and consistent visual impact.

Pre-Application Surface Preparation: The Foundation of Performance

Surface preparation represents the most critical factor determining vinyl sticker longevity, yet it’s often given insufficient attention during installation. Proper preparation creates optimal bonding conditions while eliminating contaminants that could compromise adhesive performance or cause premature failure.

Thorough cleaning removes oils, dust, moisture, and chemical residues that interfere with adhesive bonding. The cleaning process should progress from gross contamination removal through final surface preparation using appropriate solvents and techniques. Industrial applications might require specialized cleaning agents to remove process oils, while outdoor applications need thorough dust and oxidation removal for optimal results.

Surface temperature during application significantly affects initial bond formation and long-term performance. Professional application techniques recommend surface temperatures between 15-25°C for optimal adhesive flow and bonding. Cold surfaces prevent proper adhesive wetting and can trap moisture under vinyl films, while excessive heat can cause premature adhesive curing that reduces bond strength.

Humidity control during application prevents moisture entrapment that could cause blistering and adhesive failure. High humidity environments require careful timing and potentially dehumidification to ensure optimal bonding conditions. Australian coastal regions often require special attention to humidity management during critical applications.

Surface texture evaluation determines whether standard adhesive formulations will achieve adequate bonding or whether specialized high-tack alternatives are necessary. Rough or textured surfaces require adhesives that can flow into surface irregularities and create mechanical bonds that standard formulations cannot achieve.

Optimal Application Techniques for Professional Results

Proper application technique determines both immediate appearance and long-term performance of vinyl stickers. Professional installers follow systematic approaches that ensure complete adhesive contact while eliminating air entrapment and stress concentrations that could cause future failures.

Positioning accuracy prevents the need for repositioning that can compromise adhesive bonds. Professional installers use registration marks, templates, or measurement systems to ensure precise placement before initial contact. Once adhesive contact begins, repositioning becomes increasingly difficult and potentially damaging to both vinyl and substrate.

Squeegee technique affects both immediate appearance and long-term adhesion quality. Proper technique uses overlapping strokes with consistent pressure to progressively eliminate air bubbles while ensuring complete adhesive contact. The squeegee angle, pressure, and stroke pattern must be adapted to vinyl thickness and surface curvature for optimal results.

Edge sealing represents a critical final step that prevents moisture infiltration and edge lifting. Post-heating with appropriate temperature settings activates adhesive chemistry and improves conformability on curved surfaces. Professional installers understand the relationship between temperature, pressure, and time needed to achieve optimal edge sealing without damaging vinyl materials.

Complex surface applications require specialized techniques including relief cuts, stretching procedures, and compound curve forming that demand professional expertise. Attempting complex installations without proper training and equipment often results in premature failures that could have been prevented through professional application.

Post-Application Protection Strategies

Protecting newly installed vinyl stickers during their critical curing period significantly improves long-term performance and appearance retention. Understanding post-application requirements prevents common mistakes that compromise otherwise professional installations.

Curing time requirements vary with temperature, humidity, and adhesive formulation but typically require 24-48 hours for full bond development. During this period, vinyl stickers remain vulnerable to edge lifting and adhesive displacement that can cause permanent performance problems. Protecting installations from excessive moisture, mechanical stress, and temperature extremes during curing optimizes final performance.

Lamination options provide additional protection for critical applications where maximum durability justifies additional cost. Clear protective films resist scratching, UV exposure, and chemical attack while allowing easy cleaning and maintenance. The decision to laminate should consider application requirements, environmental exposure, and cost-benefit analysis.

UV protective coatings can extend vinyl lifecycles in extreme exposure conditions where standard UV stabilizers might prove insufficient. These specialized treatments absorb harmful radiation before it reaches vinyl substrates while maintaining transparency and appearance. The cost and application complexity of protective coatings must be balanced against expected lifespan extensions.

Routine Maintenance Schedules and Procedures

Systematic maintenance extends vinyl sticker lifecycles while maintaining professional appearance and preventing small problems from becoming major failures. Maintenance protocols should be adapted to specific environmental conditions and application requirements.

Regular cleaning prevents accumulation of contaminants that can cause staining, surface degradation, or adhesive compromise. Appropriate cleaning frequency depends on environmental exposure but typically ranges from weekly for harsh industrial conditions to monthly for protected indoor applications. Cleaning technique and product selection must avoid damage to vinyl surfaces while effectively removing accumulated contamination.

Inspection schedules help identify emerging problems before they become significant failures. Regular inspection should focus on edge condition, color consistency, adhesive bond integrity, and surface condition changes that might indicate developing problems. Early intervention through cleaning, re-sealing, or protective treatment can significantly extend useful lifecycles.

Edge maintenance represents a critical aspect of vinyl sticker longevity. Edge lifting, if detected early, can often be corrected through cleaning and re-activation techniques that restore adhesive bonds. Allowing edge lifting to progress typically requires complete replacement, making regular edge inspection particularly valuable.

Environmental monitoring helps predict maintenance requirements and replacement timing. Understanding seasonal stress patterns enables proactive maintenance scheduling that prevents failures during critical periods while optimizing maintenance efficiency.

Common Mistakes and Avoidance Strategies

Understanding common vinyl sticker failures and their prevention strategies helps achieve professional results while avoiding costly mistakes that compromise performance and appearance.

Improper surface preparation causes more vinyl sticker failures than any other single factor. Rushing through cleaning procedures or using inappropriate cleaning agents creates contaminated bonding surfaces that prevent proper adhesive performance. Surface preparation guides provide systematic approaches that ensure optimal bonding conditions.

Incorrect material selection for specific applications often results in premature failures that could have been prevented through proper vinyl and adhesive selection. Understanding application requirements and environmental conditions enables informed material choices that optimize performance and value.

Improper application technique creates stress concentrations, air entrapment, and incomplete bonding that reduce performance and appearance quality. Professional training and proper tools enable application techniques that maximize vinyl sticker potential while avoiding common installation problems.

Inadequate maintenance allows small problems to develop into major failures that require complete replacement. Understanding maintenance requirements and implementing systematic care procedures prevents most premature failures while maintaining professional appearance throughout vinyl lifecycles.

Environmental exposure beyond material capabilities causes predictable failures that can be prevented through appropriate material selection and protection strategies. Understanding environmental challenges and selecting materials with appropriate performance capabilities prevents expensive failures and replacement costs.

Armed with knowledge about materials, applications, durability, and care, you’re now ready to make informed decisions about selecting the perfect vinyl sticker solution for your specific needs.

Selecting optimal vinyl sticker solutions requires systematic evaluation of application requirements, environmental conditions, performance expectations, and budget constraints. This decision-making framework synthesizes technical knowledge into practical guidance that ensures successful outcomes while maximizing value and performance across diverse Australian applications.

Application Assessment and Requirements Analysis

The foundation of successful vinyl sticker selection lies in thoroughly understanding your specific application requirements and translating those needs into technical specifications that guide material selection. This systematic approach prevents costly mistakes while ensuring optimal performance for your unique circumstances.

Duration requirements represent the primary selection criterion, with expected service life determining appropriate material grades and adhesive formulations. Temporary applications lasting weeks or months can utilize economical calendared vinyl with removable adhesives, while permanent installations requiring 5-7 year lifecycles demand premium cast vinyl with permanent adhesive systems. Understanding your timeline requirements enables appropriate material selection that balances cost with performance.

Surface characteristics significantly influence adhesive selection and application techniques. Smooth, non-porous surfaces like glass or painted metal accommodate standard adhesive formulations, while textured plastics or powder-coated surfaces require high-tack adhesives for reliable bonding. Low-surface-energy materials like polyethylene might need specialized primers or adhesive promoters for adequate bond strength.

Environmental exposure assessment determines necessary protection levels and material grades. Indoor applications with minimal UV exposure and controlled temperatures can utilize standard vinyl formulations, while outdoor applications in Australian conditions require UV-stabilized materials with enhanced weather resistance. Harsh industrial environments might demand specialized chemical-resistant or high-temperature formulations.

Aesthetic requirements influence finish selection, color choices, and printing specifications. High-visibility applications benefit from gloss finishes that maximize color impact, while sophisticated branding might prefer matte finishes for premium appearance. Color critical applications require discussion of color matching procedures and fade resistance characteristics.

Regional Climate Considerations and Material Matching

Australia’s diverse climate zones create specific material requirements that must be considered for optimal performance and longevity. Understanding regional challenges enables informed material selection that addresses local environmental stressors while providing reliable performance throughout expected service lifecycles.

Northern Australia’s tropical conditions demand maximum UV protection and moisture resistance for reliable outdoor performance. The combination of intense solar radiation, high humidity, and elevated temperatures accelerates vinyl degradation through multiple pathways. Premium cast vinyl with robust UV stabilizer packages and enhanced moisture resistance provides optimal performance in these demanding conditions.

Central Australia’s arid environment creates extreme temperature variations and dust exposure that challenge vinyl durability through thermal stress and abrasive wear. Materials selected for these applications must maintain flexibility across wide temperature ranges while resisting surface degradation from wind-borne particles. Cast vinyl with appropriate plasticizer systems and surface protection proves most reliable for central Australian applications.

Coastal regions throughout Australia require materials that resist salt air exposure while maintaining adhesive performance in high-humidity conditions. Marine-grade vinyl formulations with enhanced corrosion resistance and moisture tolerance provide reliable performance where standard materials might fail through osmotic stress or salt crystallization damage.

Southern Australia’s temperate climate offers more moderate conditions but still requires quality materials for extended outdoor exposure. While less demanding than tropical or arid conditions, temperate regions still experience significant UV exposure and temperature variations that challenge inferior materials. Standard commercial-grade vinyl typically provides excellent performance in these conditions.

Budget Optimization and Value Engineering

Achieving optimal value requires balancing initial material costs against expected performance and replacement frequency. This analysis often reveals that premium materials provide superior total cost of ownership through extended lifecycles and reduced maintenance requirements.

Material cost analysis should consider not only initial purchase price but also application labor, replacement frequency, and maintenance requirements throughout expected service life. Premium cast vinyl might cost 50-100% more initially than calendared alternatives but can provide 3-5 times longer service life, making it more economical for permanent applications.

Volume considerations can significantly affect material costs through quantity pricing and reduced setup charges for custom printing. Consolidating orders or planning future requirements can provide substantial savings while ensuring material consistency across projects. Professional consultation can identify optimization opportunities that might not be apparent to individual purchasers.

Performance value extends beyond simple cost calculations to include factors like professional appearance maintenance, reduced replacement labor, and avoided downtime costs. Applications where sticker failure creates operational disruption often justify premium materials through their superior reliability and extended service life.

Timeline Considerations and Project Planning

Project timelines influence both material selection and procurement strategies, with rush applications potentially limiting optimal material choices while planned projects enable comprehensive optimization for performance and value.

Custom material requirements typically require 2-4 weeks for procurement and processing, making early planning essential for optimal material selection. Standard materials might be available immediately but could compromise performance or appearance if they don’t match specific application requirements perfectly.

Seasonal timing considerations can significantly affect installation conditions and initial performance. Planning installations during moderate weather conditions improves application quality while allowing optimal curing conditions for maximum long-term performance. Australian summer conditions often challenge installation procedures while winter moisture can complicate adhesive curing.

Production scheduling must account for weather windows, surface access, and operational requirements that might affect installation timing. Complex projects benefit from detailed planning that coordinates material procurement, installation conditions, and operational requirements for optimal results.

Professional Consultation Benefits and Expert Guidance

Complex applications often benefit from professional consultation that leverages experience and technical knowledge to optimize material selection and installation procedures. Understanding when to seek expert advice can prevent costly mistakes while ensuring optimal performance for challenging applications.

Technical applications requiring specialized materials or procedures often exceed general knowledge boundaries where professional expertise becomes invaluable. Industrial environments with chemical exposure, extreme temperatures, or critical safety requirements need expert material selection and application guidance to ensure reliable performance and regulatory compliance.

Large-scale projects benefit from professional planning that optimizes material selection, installation procedures, and maintenance requirements for maximum value and performance. The complexity of coordinating multiple factors often requires professional project management to achieve optimal results efficiently.

Custom requirements including specific colors, sizes, or performance characteristics often require professional consultation to identify optimal solutions and ensure realistic expectations. Professional suppliers understand material capabilities and limitations that enable informed decision-making for unique applications.

Quality assurance considerations include material sourcing, application oversight, and performance monitoring that professional suppliers can provide through established quality systems and experience. The cost of professional consultation often proves minimal compared to the value of avoided problems and optimized performance.

Quality Assurance and Supplier Selection

Choosing reputable suppliers with proven track records in Australian conditions ensures access to quality materials, reliable service, and ongoing support throughout project lifecycles. Understanding supplier capabilities and limitations enables informed purchasing decisions that support optimal outcomes.

Material sourcing from established manufacturers with Australian testing and certification provides confidence in performance claims and warranty coverage. Locally tested materials account for Australian environmental conditions while providing recourse through established warranty and support systems.

Technical support availability helps resolve application challenges and optimize performance through expert guidance when problems arise. Suppliers with strong technical support capabilities provide valuable resources that extend beyond initial material supply to encompass long-term success.

Installation support or training might be available for complex applications where proper technique significantly affects outcomes. Professional installation services or training programs can ensure optimal results while building internal capabilities for future projects.

Performance tracking and warranty support provide ongoing assurance that materials will meet performance expectations while offering recourse if problems develop. Understanding warranty terms and supplier support capabilities provides additional value beyond initial material supply.

With this comprehensive understanding of vinyl stickers, you’re equipped to make informed decisions that ensure your projects deliver lasting results in Australia’s demanding conditions.

Australia’s diverse climate conditions—from the intense UV radiation of the Northern Territory to the coastal humidity of Queensland—demand vinyl stickers that can perform consistently while maintaining their visual impact and adhesive integrity. Understanding the fundamental differences between cast and calendared vinyl, selecting appropriate adhesive types, and implementing proper care practices are essential for achieving optimal results that withstand our continent’s unique environmental challenges.

Whether you’re creating automotive graphics that need to withstand highway conditions and extreme temperatures, developing business signage for storefront applications that must maintain professional appearance through seasonal weather variations, or designing personal labels for outdoor equipment that faces constant UV exposure and handling, the right vinyl sticker solution combines technical performance with visual appeal to deliver exceptional value over extended service lifecycles.

The key to success lies in matching your specific requirements with appropriate materials, understanding your local environmental factors, and partnering with experienced professionals who understand Australian conditions and applications. Quality vinyl stickers represent investments in professional appearance, operational efficiency, and brand consistency that deliver measurable returns through extended performance and reduced replacement frequency.

Professional consultation and expert material selection transform vinyl stickers from simple adhesive products into strategic business tools that support operational excellence while maintaining cost-effectiveness. The knowledge gained from understanding materials, applications, environmental factors, and maintenance requirements empowers informed decision-making that maximizes value while ensuring reliable performance throughout demanding Australian conditions.

Transform your ideas into durable, professional vinyl stickers designed specifically for Australian conditions. FastStickers combines over 15 years of local expertise with lightning-fast turnaround times and premium materials engineered to withstand our continent’s demanding climate while delivering exceptional visual impact and long-term value.

Our comprehensive understanding of Australian environmental challenges, combined with access to premium vinyl materials and advanced printing technologies, ensures your projects achieve professional results that maintain their appearance and performance throughout extended service lifecycles. From specialized high-tack applications for challenging surfaces to removable solutions for temporary requirements, we provide expert guidance that matches optimal materials to your specific needs and environmental conditions.

Take the next step toward vinyl sticker success:

Explore our complete range of vinyl sticker solutions designed specifically for Australian applications and environmental demands.

Request expert consultation with our technical team for personalized material recommendations and application guidance.

Get an instant quote for your custom vinyl sticker project with transparent pricing and professional specifications.

Don’t let Australia’s harsh conditions compromise your message or professional appearance. Trust the vinyl sticker specialists who understand what it takes to deliver lasting results across our diverse and demanding continent, backed by proven expertise and unwavering commitment to customer success.

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

The Complete Guide to Candle Labels: Design, Materials & Australian Compliance Australia’s candle market is experiencing unprecedented growth, with handcrafted and artisanal candles driving a $200+

The Aussie Choice for a Greener Tomorrow Eco-friendly stickers are no longer a niche choice—they’re quickly becoming the go-to for Aussie businesses and event organisers

Choosing the Perfect Sticker Type for Your Project: A Quick Guide Picking the right sticker can make or break your project. Many get stuck choosing

Harnessing Gippsland’s Printing Expertise for Australian Business Success Most Australian businesses settle for slow, generic printing from big companies. You don’t have to. Gippsland printing