QR Code Stickers Australia

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

Picture this: you’ve invested months developing the perfect food product, secured distribution partners, and launched with enthusiasm—only to face a devastating product recall because your label failed to properly declare allergens in bold text. In Australia, this scenario plays out more frequently than most business owners realize, with 51% of the 75 food recalls in 2023 caused by undeclared allergens. The financial consequences? Recalls can cost hundreds of thousands to millions of dollars, while compliance failures can trigger fines reaching $550,000 for corporations in some Australian jurisdictions.

For Australian food businesses, the difference between success and catastrophe often comes down to a simple piece of adhesive paper: your food label sticker. Yet despite their critical importance, many business owners treat labeling as an afterthought, focusing on product development while leaving compliance to chance. This approach is not just risky—it’s financially reckless.

The regulatory landscape governing Australian food labels has never been more complex or strictly enforced. From the February 2024 Plain English Allergen Labelling (PEAL) requirements to the impending mandatory Health Star Rating system expected by 2026, staying compliant requires more than basic awareness—it demands strategic planning and expert execution.

This comprehensive guide cuts through the complexity to give you everything you need: a thorough understanding of current FSANZ requirements, practical strategies for choosing the right label materials, design best practices that balance compliance with brand appeal, and insider knowledge on avoiding the costly mistakes that trap unsuspecting businesses. Whether you’re a startup artisan producer or an established manufacturer preparing for retail expansion, the insights in this guide will transform your labeling from a compliance burden into a competitive advantage.

Picture this: you’ve invested months developing the perfect food product, secured distribution partners, and launched with enthusiasm—only to face a devastating product recall because your label failed to properly declare allergens in bold text. In Australia, this scenario plays out more frequently than most business owners realize, with 51% of the 75 food recalls in 2023 caused by undeclared allergens. The financial consequences? Recalls can cost hundreds of thousands to millions of dollars, while compliance failures can trigger fines reaching $550,000 for corporations in some Australian jurisdictions.

For Australian food businesses, the difference between success and catastrophe often comes down to a simple piece of adhesive paper: your food label sticker. Yet despite their critical importance, many business owners treat labeling as an afterthought, focusing on product development while leaving compliance to chance. This approach is not just risky—it’s financially reckless.

The regulatory landscape governing Australian food labels has never been more complex or strictly enforced. From the February 2024 Plain English Allergen Labelling (PEAL) requirements to the impending mandatory Health Star Rating system expected by 2026, staying compliant requires more than basic awareness—it demands strategic planning and expert execution.

This comprehensive guide cuts through the complexity to give you everything you need: a thorough understanding of current FSANZ requirements, practical strategies for choosing the right label materials, design best practices that balance compliance with brand appeal, and insider knowledge on avoiding the costly mistakes that trap unsuspecting businesses. Whether you’re a startup artisan producer or an established manufacturer preparing for retail expansion, the insights in this guide will transform your labeling from a compliance burden into a competitive advantage.

Most importantly, you’ll discover how partnering with the right Australian label supplier can streamline your entire process, ensuring you get compliant, durable, attractive food label stickers delivered quickly when you need them most. In an industry where timing is everything and mistakes are expensive, having the right labeling strategy isn’t just helpful—it’s essential for long-term business survival and growth.

The foundation of every successful Australian food business rests on a simple but non-negotiable principle: absolute compliance with the Australia New Zealand Food Standards Code. Administered by Food Standards Australia New Zealand (FSANZ), this comprehensive regulatory framework doesn’t just suggest labeling requirements—it mandates them with the full force of Australian law.

FSANZ operates as the binational food regulator responsible for developing food standards that apply across Australia and New Zealand. Since its establishment, FSANZ has evolved into one of the world’s most sophisticated food safety organizations, with standards that cover everything from permitted ingredients to mandatory labeling requirements. For Australian food businesses, understanding FSANZ isn’t optional—it’s the difference between operating legally and facing potentially business-ending penalties.

The legal obligations extend to every packaged food product sold in Australia, with virtually no exceptions for small businesses or artisan producers. Whether you’re producing homemade preserves for local farmers markets or manufacturing products for national supermarket chains, your labels must comply with the same stringent standards. This universal application reflects Australia’s commitment to consumer protection and ensures that every Australian can make informed food choices regardless of where they shop.

The financial stakes of non-compliance are staggering and getting more severe each year. In New South Wales alone, businesses face fines of up to $82,000 for individuals and $412,500 for corporations for lesser labeling offenses. More serious violations—such as selling mislabeled food that poses health risks—can trigger penalties of $110,000 or two years imprisonment for individuals, and up to $550,000 for corporations. Victoria maintains similarly aggressive penalty structures, with fines ranging from $75,000 to $100,000 for individuals and $375,000 to $500,000 for corporations. FSANZ itself can levy fines up to $275,000 for Code violations.

Beyond immediate financial penalties, the reputational damage from compliance failures can permanently destroy brand equity built over years. Modern consumers are increasingly sophisticated about food safety and labeling requirements. A single recall notice or media report about labeling violations can trigger lasting consumer distrust, retail delisting, and competitive disadvantage that extends far beyond the immediate incident.

Recent regulatory changes have heightened both the complexity and enforcement rigor around food labeling. The February 2024 implementation of Plain English Allergen Labelling (PEAL) requirements marked a watershed moment for Australian food businesses. Under PEAL, allergens must now be declared using standardized, simple terminology—“milk” instead of “casein,” for example—and prominently displayed in bold font. The transition period ended on February 25, 2024, though products labeled before this date can remain in circulation until February 25, 2026, under stock-in-trade provisions.

Looking ahead, the regulatory environment will become even more demanding. The Health Star Rating system, which achieved only 37% industry adoption by November 2025, is expected to become mandatory by 2026 following a government decision anticipated in early 2026. Simultaneously, FSANZ is conducting a comprehensive review of Nutrition Information Panel requirements, likely resulting in enhanced back-of-pack labeling standards that complement mandatory front-of-pack Health Star Ratings.

These evolving requirements aren’t bureaucratic obstacles—they represent opportunities for forward-thinking businesses to gain competitive advantages. Companies that invest in superior labeling systems enjoy multiple business benefits: enhanced consumer trust through transparent communication, smoother retail approval processes, reduced legal and compliance risks, and stronger brand positioning in increasingly competitive markets.

Professional retailers, particularly major supermarket chains, increasingly demand sophisticated compliance documentation before approving new products. Businesses with robust labeling systems and clear compliance track records navigate these approval processes more efficiently, securing better shelf placement and promotional opportunities. In contrast, companies with questionable labeling practices often face extended approval delays, additional documentation requirements, and heightened ongoing scrutiny that impedes growth.

The NSW Food Authority labeling guidelines emphasize that compliance isn’t just about avoiding penalties—it’s about building consumer confidence through clear, accurate communication. Australian consumers, backed by some of the world’s strongest food safety regulations, expect and deserve complete transparency about the products they purchase.

Understanding current DAFF allergen labeling requirements is particularly crucial given the recent PEAL implementation and the ongoing focus on allergen-related recalls. With allergens responsible for the majority of Australian food recalls, businesses that excel at allergen declaration and labeling gain significant competitive advantages while protecting vulnerable consumers.

The regulatory landscape will continue evolving as consumer expectations and scientific understanding advance. Successful Australian food businesses don’t just meet current requirements—they anticipate future changes and build labeling systems that adapt efficiently to new standards. This proactive approach transforms regulatory compliance from a reactive burden into a strategic business capability that drives growth and protects long-term viability.

Now that you understand the regulatory landscape, let’s examine exactly what information must appear on every food label to ensure compliance.

Navigating Australian food labeling requirements means mastering a complex matrix of mandatory information elements, each with specific formatting, placement, and content requirements that can make or break your compliance efforts. Every element serves a distinct consumer protection purpose, and missing or incorrectly presenting even one component can trigger recalls, fines, and reputational damage.

The Nutrition Information Panel (NIP) stands as perhaps the most technically demanding labeling requirement, requiring precise nutritional analysis and specific formatting standards. Your NIP must display energy content in kilojoules, along with protein, fat (including saturated fat), carbohydrates (including sugars), and sodium content per serving and per 100 grams or 100 milliliters. The serving size you choose must reflect realistic consumption patterns—a requirement that trips up many businesses who select unrealistically small servings to make nutritional profiles appear healthier.

Calculating accurate nutritional values requires either laboratory analysis or comprehensive database research using NUTTAB or similar approved sources. Many businesses underestimate the complexity involved in NIP preparation, leading to inaccurate declarations that can trigger compliance violations. The formatting requirements are equally specific: standardized fonts, prescribed decimal places, and mandatory inclusion of percentage daily intake values for energy, protein, fat, saturated fat, carbohydrates, sugars, and sodium based on an 8,700 kilojoule daily diet.

Ingredient lists demand meticulous attention to both content accuracy and formatting requirements. Ingredients must appear in descending order by weight at the time of manufacture—a straightforward concept that becomes complex when dealing with compound ingredients, processing aids, and multi-stage manufacturing processes. The 5% threshold rule requires individual declaration of any ingredient comprising 5% or more of a compound ingredient, unless the compound ingredient itself comprises less than 5% of the final product.

Water requires special consideration in ingredient lists. If added as an ingredient, water must appear in its weight-appropriate position. However, water that forms part of other ingredients (like in tomato puree) doesn’t require separate declaration. Similarly, processing aids that don’t remain in the final product generally don’t require declaration, though this exemption has strict technical limitations that require careful evaluation.

Allergen declarations have become significantly more complex and critically important since the February 2024 PEAL implementation. The nine major allergens—cereals containing gluten, crustacea, eggs, fish, milk, molluscs, tree nuts, peanuts, and sesame—must be declared using standardized plain English terminology and highlighted in bold text. This seems straightforward until you consider the hundreds of ingredient derivatives that contain allergens: whey powder contains milk, lecithin may contain eggs or soy, and natural flavors can contain virtually any allergen.

The specificity requirements under PEAL have raised the compliance bar considerably. Instead of generic declarations like “contains nuts,” labels must now specify individual tree nuts: “contains almonds” or “contains cashews and hazelnuts.” Similarly, gluten-containing cereals require individual identification: “contains wheat” rather than simply “contains gluten.” This granular approach better serves consumers with specific allergies but demands more sophisticated ingredient tracking and supplier communication.

Cross-contamination warnings—the familiar “may contain” statements—operate under separate guidelines and shouldn’t be used as substitutes for proper allergen declarations. These warnings should reflect genuine cross-contamination risks based on your manufacturing environment, not serve as catch-all safety nets for uncertain ingredient sourcing.

Country of origin labeling combines textual declarations with graphical bar charts, creating one of the most visually complex mandatory elements. Priority food products—a category covering most basic foods like meat, seafood, fruits, vegetables, and dairy—require both explanatory text and a bar chart showing the proportion of ingredients by weight that are Australian. The bar chart must meet strict contrast, sizing, and color requirements, while the explanatory text must accurately describe the country where the food was grown, produced, made, or packed.

For non-priority foods, the requirements simplify to textual declarations only, but determining which category applies to your product requires careful analysis. Multi-ingredient products with components from different countries face particularly complex calculation and declaration requirements that often necessitate professional guidance.

Date marking decisions carry significant food safety and legal implications. “Use by” dates apply to foods that pose safety risks if consumed after the specified date—typically refrigerated products, fresh foods, and items with short shelf lives. “Best before” dates apply to foods that may lose quality but remain safe for consumption—generally shelf-stable products, frozen foods, and long-life items. Choosing the wrong date marking system can create unnecessary liability exposure or consumer confusion.

The dates themselves must follow prescribed formatting (day/month/year for periods under two years, month/year for longer periods) and link appropriately to storage instructions. Products requiring refrigeration must include both temperature instructions and date marking that reflects proper storage conditions.

Storage instructions must accurately reflect the conditions necessary to maintain food safety and quality until the marked date. Generic phrases like “store in a cool, dry place” often prove inadequate for products with specific temperature, humidity, or light sensitivity requirements. The instructions must be specific enough that consumers can reasonably achieve the necessary storage conditions in typical domestic environments.

Supplier information requires the name and Australian or New Zealand address of the business ultimately responsible for the food. This isn’t necessarily the manufacturer—for imported products, it’s typically the importer; for contract-manufactured products, it’s usually the brand owner. The address must be sufficient for consumer contact and regulatory correspondence, meaning post office boxes generally don’t satisfy this requirement.

Special considerations apply to imported foods, which face additional declaration requirements around import permits, overseas manufacturing standards, and sometimes quarantine clearance information. Small business exemptions exist for certain labeling requirements, but these exemptions have strict revenue and distribution limitations that many growing businesses quickly exceed.

The Food labeling for importers guide provides crucial guidance for businesses bringing international products into the Australian market, while Country of origin labeling basics offers detailed technical guidance on implementing the bar chart and textual requirements that challenge many manufacturers.

Creating a comprehensive labeling checklist becomes essential for maintaining consistent compliance across product lines and production runs. Your checklist should cover not just content requirements but also formatting, placement, and legibility standards that ensure every label meets both legal requirements and practical usability standards.

With the mandatory information requirements clear, the next crucial decision is selecting label materials that will maintain this information’s integrity throughout your product’s lifecycle.

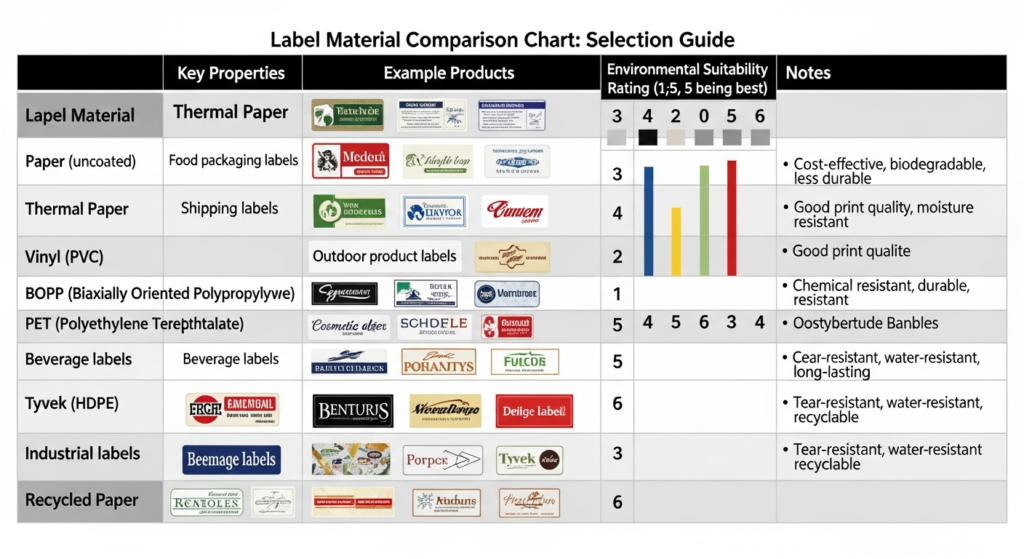

The material foundation of your food label stickers determines not just aesthetic appeal, but fundamental compliance integrity throughout your product’s entire distribution and storage lifecycle. Selecting inappropriate materials can transform perfectly compliant label content into illegible, peeling, or contaminated failures that trigger recalls and undermine consumer confidence. Understanding the performance characteristics of different label materials empowers you to make informed decisions that protect both your product and your business.

Paper-based label materials offer cost-effectiveness and printability advantages that make them attractive for many food applications, particularly dry goods with stable storage conditions. Standard coated papers provide excellent print quality and are compatible with most commercial printing processes, making them ideal for products stored at room temperature with minimal moisture exposure. However, paper’s inherent vulnerability to moisture, oils, and temperature fluctuations requires careful application consideration.

For products with moderate moisture exposure—such as condiments stored in refrigerators or items prone to condensation—laminated paper constructions provide enhanced durability. The lamination process bonds a clear protective film over the printed surface, creating moisture barriers while maintaining paper’s printing advantages and cost benefits. This hybrid approach works particularly well for products that need refrigeration but don’t face constant moisture exposure.

Polypropylene (PP) labels represent the workhouse material for refrigerated food products, offering superior moisture resistance and flexibility that accommodates package movement during transportation and handling. PP’s molecular structure provides excellent resistance to oils, acids, and alkaline conditions commonly encountered in food processing and storage environments. The material’s clarity allows for vibrant print reproduction while maintaining dimensional stability across temperature ranges typical in cold chain distribution.

PP labels excel in applications requiring moderate chemical resistance, such as dairy products, fresh produce, and prepared foods with acidic components. The material’s flexibility prevents cracking and peeling when packages are squeezed, bent, or subjected to thermal cycling during distribution. For products requiring extended refrigerated storage, PP’s consistent adhesive compatibility ensures labels remain securely attached throughout extended shelf life periods.

Polyethylene (PE) labels shine in frozen food applications and flexible packaging scenarios where extreme temperature resistance becomes paramount. PE’s unique properties allow it to remain flexible and maintain adhesive bonds at temperatures as low as -20°C, making it essential for frozen foods, ice cream products, and items distributed through frozen supply chains. The material’s conformability allows it to adhere effectively to irregular surfaces and flexible packaging that changes shape during handling.

The choice between different PE formulations depends on specific application requirements. Low-density polyethylene (LDPE) offers maximum flexibility and is ideal for squeeze bottles, flexible pouches, and products requiring maximum conformability. High-density polyethylene (HDPE) provides enhanced durability and chemical resistance while maintaining good low-temperature performance, making it suitable for frozen foods requiring long-term storage stability.

Polyester (PET) labels deliver maximum durability and chemical resistance for products facing harsh storage conditions or extended shelf life requirements. PET’s molecular structure provides exceptional resistance to UV light, extreme temperatures, chemicals, and mechanical stress that would destroy other label materials. This makes PET ideal for products stored in direct sunlight, outdoor retail environments, or industrial kitchens where cleaning chemicals and high temperatures are common.

The superior dimensional stability of PET prevents label shrinkage, expansion, or distortion during temperature cycling, ensuring critical information remains legible and barcodes remain scannable throughout the product lifecycle. For premium products requiring long-term aesthetic appeal, PET labels maintain color vibrancy and print quality significantly longer than paper or other synthetic alternatives.

Vinyl labels provide the ultimate waterproof performance for products requiring maximum moisture resistance or outdoor exposure. Vinyl’s thick construction and aggressive adhesive systems create virtually impermeable barriers against water, oils, and atmospheric moisture. These characteristics make vinyl particularly valuable for products stored in high-humidity environments, outdoor retail displays, or applications requiring frequent cleaning and sanitization.

However, vinyl’s superior performance comes with increased cost and thickness that may create application challenges. The material’s stiffness can make application to small containers or curved surfaces more difficult, and the increased thickness may interfere with automated dispensing equipment or packaging machinery.

Specialty materials open unique branding and performance opportunities for products requiring distinctive positioning or specific performance characteristics. Kraft paper labels create artisanal, environmentally conscious brand impressions perfect for organic, natural, or heritage food products. The uncoated texture and natural appearance resonate with consumers seeking authentic, traditional food experiences.

Metallic foil labels—typically aluminum or metallized polyester—create premium brand positioning ideal for luxury food items, gift products, or seasonal specialties. The reflective surfaces and rich color reproduction capabilities justify higher material costs for products commanding premium pricing. However, foil materials require careful consideration of printing compatibility and application environment, as they can be more sensitive to scratching and creasing.

Clear film labels create “no-label” appearances that showcase product contents while maintaining required information compliance. These materials work particularly well for beverages, sauces, and products where package design benefits from unobstructed visibility. Clear films require careful attention to print contrast and background considerations to ensure readability compliance.

Adhesive selection often proves as critical as face material choice, with different formulations optimized for specific application requirements and environmental conditions. Permanent adhesives create irreversible bonds suitable for most food applications where label removal isn’t necessary. These adhesives typically offer the highest bond strength and best long-term performance under varying environmental conditions.

Removable adhesives allow clean label removal without residue, making them valuable for reusable containers, gift products, or applications where end-users may want to remove labels. However, removable adhesives generally offer lower bond strength and may be more susceptible to edge lifting or failure under challenging environmental conditions.

Freezer-grade adhesives maintain bonding effectiveness at sub-zero temperatures where standard adhesives become brittle and fail. These specialized formulations remain flexible and maintain adhesive properties down to -20°C or lower, ensuring frozen food labels remain attached throughout distribution and storage. The performance difference between standard and freezer-grade adhesives becomes particularly critical for products experiencing thermal cycling between frozen storage and display environments.

Environmental considerations extend beyond temperature to include humidity, oil exposure, and UV light exposure that can degrade both label materials and adhesive systems. Products stored in high-humidity environments require both moisture-resistant face materials and adhesives formulated to resist humidity-induced bond failure. Similarly, products exposed to oils—either from content migration or processing environments—need adhesives specifically designed for oil resistance.

Creating a material selection matrix helps systematize decision-making by correlating product characteristics, storage conditions, and performance requirements with appropriate material options. Consider factors including storage temperature range, moisture exposure, chemical contact, mechanical stress, shelf life duration, and aesthetic requirements to narrow material choices to optimal solutions.

Once you’ve selected the appropriate material, the design phase requires careful balance between regulatory compliance and brand appeal.

Masterful food label design seamlessly integrates mandatory regulatory elements with compelling brand messaging, creating labels that simultaneously ensure compliance and drive purchase decisions. The challenge lies in transforming dense informational requirements into visually appealing, user-friendly designs that enhance rather than compromise brand identity. Success demands understanding both regulatory specifications and consumer psychology, then applying design principles that serve both masters effectively.

Typography foundation establishes the framework for all other design decisions, with font selection and sizing directly impacting both regulatory compliance and brand personality. FSANZ regulations specify minimum font sizes for different label elements: 3mm for most mandatory information, with specific requirements for nutrition panels and allergen declarations that may require larger fonts depending on label size and format. However, minimum compliance represents only the starting point—effective design often requires substantially larger fonts to ensure practical readability.

Selecting appropriate typefaces requires balancing legibility requirements with brand personality considerations. Sans-serif fonts typically provide superior readability at small sizes, making them ideal for nutritional information, ingredient lists, and regulatory text. However, serif fonts can enhance brand sophistication and traditional positioning, particularly for artisanal or premium products. The key lies in creating font hierarchies that use highly legible fonts for compliance-critical information while incorporating brand-appropriate fonts for marketing elements.

Font weight and style variations help create information hierarchy without compromising readability. Bold weights naturally emphasize critical information like allergen declarations, while regular weights provide readability for detailed information like ingredient lists. Italic styles can add elegance to brand names or product descriptions but should be used sparingly for regulatory information where maximum clarity is essential.

Allergen highlighting techniques have become significantly more critical since the February 2024 PEAL implementation, requiring bold formatting that remains visually integrated with overall label design. The regulation mandates bold text for allergen declarations, but effective design treats this requirement as an opportunity rather than a constraint. Strategic use of bold formatting can create visual emphasis that enhances both compliance and consumer awareness.

Color coordination offers additional allergen emphasis opportunities while maintaining design harmony. Using consistent color schemes for allergen information—such as a specific colored background or border—creates visual patterns that help allergen-sensitive consumers quickly locate critical information. However, color coding should supplement, not replace, required bold text formatting, as color perception varies among consumers and some may have color vision limitations.

Positioning allergen information strategically within the label layout ensures prominence without disrupting overall design flow. Placing allergen declarations near ingredient lists creates logical information grouping, while prominent positioning near the front panel increases visibility for time-pressed shoppers. Some successful designs create dedicated allergen sections with subtle graphic elements that draw attention without overwhelming other label elements.

Information hierarchy principles guide readers’ attention through complex label information in logical progression, ensuring critical elements receive appropriate emphasis while maintaining visual appeal. Primary hierarchy typically focuses on brand identity and product positioning, using largest fonts, prominent positioning, and eye-catching design elements to establish immediate brand recognition and purchase appeal.

Secondary hierarchy encompasses critical consumer information including product name, flavor or variety, and key selling points like organic certification or premium ingredients. This information requires substantial visual emphasis while integrating harmoniously with primary brand elements. Effective designs create clear visual relationships between brand identity and product specifics.

Tertiary hierarchy covers mandatory regulatory information including nutrition panels, ingredient lists, and storage instructions. While these elements require compliance-appropriate sizing and positioning, thoughtful design can present this information in visually organized, easily accessible formats that enhance rather than detract from overall label appeal.

Color psychology in food packaging leverages subconscious consumer responses to different colors, creating appetite appeal and emotional connections that influence purchase decisions. Warm colors like reds, oranges, and yellows typically stimulate appetite and convey energy, freshness, and excitement—making them effective for snack foods, beverages, and products targeting younger demographics.

Cool colors including blues, greens, and purples often communicate health, naturalness, and premium quality. Green especially resonates with organic, natural, and environmentally conscious positioning, while blue can suggest freshness and purity, particularly effective for dairy and water products. Purple traditionally conveys luxury and premium positioning, though it requires careful application in food contexts as it occurs rarely in natural foods.

However, color psychology must be balanced against practical readability requirements, particularly for mandatory regulatory text. High contrast between text and background colors ensures compliance with legibility standards while supporting accessibility for consumers with visual limitations. Black text on white or light backgrounds typically provides optimal contrast, though other high-contrast combinations can work effectively when properly tested.

Layout optimization techniques maximize limited label space while ensuring all mandatory elements receive appropriate presentation. Grid-based design systems create visual organization that accommodates varying amounts of information while maintaining consistent brand presentation across product lines. Flexible grid systems adapt to different container sizes and shapes while preserving essential design relationships.

White space utilization prevents visual overcrowding while creating sophisticated, premium appearances that justify higher pricing. Strategic white space around key elements like brand names, product descriptions, and allergen information creates visual breathing room that enhances readability and perceived quality. However, white space must be balanced against information density requirements inherent in comprehensive food labeling.

Visual grouping techniques help organize related information elements while creating clear separation between different information types. Subtle background colors, borders, or spacing can create distinct zones for nutrition information, ingredients, and marketing claims without requiring additional space or disrupting overall design harmony.

Multilingual considerations are increasingly important in Australia’s diverse market landscape, with many successful food businesses incorporating multiple languages to serve broader consumer bases. Effective multilingual labeling requires careful space planning and hierarchical organization to ensure all languages receive appropriate emphasis while maintaining compliance requirements.

When incorporating multiple languages, consider both legal requirements and market opportunities. While English remains mandatory for all Australian food labels, adding other languages can unlock significant market segments while demonstrating cultural sensitivity and inclusiveness. However, space limitations require strategic decisions about which information to translate and how to organize multilingual content effectively.

Accessibility design principles ensure labels serve all consumers effectively, including those with visual limitations, color blindness, or reading difficulties. High contrast ratios benefit not just compliance requirements but also elderly consumers and those with declining vision. Simple, clear fonts enhance readability for consumers with dyslexia or other reading challenges.

Size and spacing considerations extend beyond minimum legal requirements to practical usability in real shopping environments. Labels that are technically compliant may still fail to serve consumers effectively in dim retail lighting or when viewed quickly during busy shopping trips. Designing for accessibility often improves usability for all consumers while demonstrating social responsibility.

The Food labeling compliance guidelines provide specific technical guidance on achieving appropriate contrast and legibility standards while maintaining design flexibility.

Brand consistency across product lines becomes increasingly important as businesses expand their offerings, requiring design systems that accommodate different products while maintaining recognizable brand identity. Successful systems establish core design elements—colors, fonts, layout principles—that remain consistent while allowing flexibility for product-specific requirements.

Template-based design systems streamline both initial design and ongoing maintenance while ensuring consistency across all products. Well-designed templates accommodate varying information requirements while maintaining essential brand relationships and compliance standards. These systems particularly benefit businesses with multiple products or frequent product launches.

Even with the best design intentions, certain common mistakes can undermine both compliance and brand effectiveness.

The road to food labeling compliance is littered with expensive mistakes that have cost Australian businesses millions in recalls, fines, and lost consumer confidence. Understanding the most frequent pitfalls and implementing systematic prevention strategies can save your business from joining the unfortunate ranks of companies that learned these lessons the hard way. Each mistake represents not just immediate financial consequences but potential long-term damage to brand reputation and market position.

Allergen visibility failures represent the single most dangerous labeling mistake, responsible for the majority of food recalls and serious consumer safety incidents. Since the February 2024 PEAL implementation, the requirements for allergen declaration have become more specific and stringent, yet many businesses continue to make critical errors that render their allergen information ineffective or non-compliant.

The most common allergen mistake involves embedding allergen information within ingredient lists without proper emphasis. Pre-PEAL practices allowed allergen information to appear only within ingredient lists, but current requirements mandate bold formatting and often separate allergen statements that can’t be missed by consumers scanning labels quickly. A simple ingredient list reading “wheat flour, eggs, milk powder” without additional emphasis fails current standards, even though the allergens are technically declared.

Another frequent error involves using outdated terminology that doesn’t meet PEAL standards. Labels declaring “contains dairy” instead of “contains milk” or “contains nuts” without specifying individual tree nuts fail to meet current plain English requirements. These seemingly minor terminology differences can trigger immediate compliance violations and recall notices.

Cross-contamination warnings present another area of frequent confusion. Businesses often use generic “may contain” statements as catch-all safety measures without conducting proper risk assessments of their manufacturing environments. Inappropriate use of these warnings can actually increase legal liability while providing false security about actual allergen management practices.

Ingredient list inaccuracies create compliance vulnerabilities that extend far beyond simple administrative errors. The requirement for ingredients to appear in descending order by weight sounds straightforward but becomes complex in real manufacturing environments with variable formulations, seasonal ingredient substitutions, and multi-stage production processes.

Recipe changes represent a particularly dangerous pitfall when label updates lag behind formulation modifications. Businesses often update their actual product formulations—responding to supply chain issues, cost pressures, or quality improvements—without immediately updating corresponding label information. This disconnect can result in labels that no longer accurately represent actual product contents, creating compliance violations and potential safety issues.

Compound ingredient declarations frequently trip up manufacturers who fail to properly understand the 5% threshold rules. When compound ingredients like “tomato sauce” comprise significant portions of a product, individual ingredients within that compound ingredient may require separate declaration. Missing these requirements can result in incomplete ingredient lists that fail regulatory standards.

Supplier ingredient changes present ongoing compliance challenges, particularly for businesses using contract manufacturers or complex supply chains. When suppliers modify their formulations—often for legitimate business reasons—downstream manufacturers may not receive timely notification, resulting in labels that no longer reflect actual product contents.

Country of origin errors have become increasingly common as businesses struggle with the complex calculation and presentation requirements introduced in recent years. The requirement for both bar charts and explanatory text creates multiple opportunities for errors, while the calculation methodology for determining Australian content percentages often proves more complex than anticipated.

Mathematical errors in calculating Australian content percentages represent the most frequent country of origin mistake. The calculations require weighing ingredients by their raw weight at manufacture, not their finished weight in the product, leading to significant calculation complexity for products with processed ingredients, added water, or ingredients that lose weight during processing.

Bar chart presentation errors include insufficient contrast between chart elements and background, incorrect sizing relative to overall label dimensions, and poor placement that renders the information difficult to locate. These technical requirements exist for good reason—poorly presented country of origin information fails to serve consumers effectively—but their precision requirements often challenge businesses accustomed to more flexible design approaches.

Misleading claims represent perhaps the most legally perilous category of labeling mistakes, as they can trigger both regulatory enforcement and consumer protection law violations. The temptation to use appealing but unsupported marketing language can lead businesses into serious legal trouble, particularly around health, nutrition, and environmental claims.

“Natural” claims frequently exceed supportable boundaries, particularly for products containing processed ingredients, artificial flavors, or synthetic vitamins. While “natural” resonates strongly with consumers, the term has specific legal definitions that many products cannot legitimately meet. Using “natural” inappropriately can trigger immediate regulatory action and consumer lawsuits.

Nutritional claims face strict substantiation requirements that many businesses underestimate. Claims like “low fat,” “high protein,” or “source of fiber” have precise technical definitions that require verification through proper nutritional analysis. Making these claims without proper substantiation can result in immediate compliance violations and mandatory label corrections.

Environmental claims including “eco-friendly,” “sustainable,” or “carbon neutral” require comprehensive life-cycle analysis and third-party verification that most food businesses cannot legitimately support. The Australian Competition and Consumer Commission (ACCC) has increased enforcement activity around environmental claims, making unsupported green marketing particularly risky.

Date marking confusion creates both compliance and liability issues, particularly around the critical decision between “use by” and “best before” dating systems. Choosing the inappropriate date marking system can expose businesses to unnecessary liability while confusing consumers about actual product safety timeframes.

The most dangerous mistake involves using “best before” dates for products that actually pose safety risks after expiration. Products containing fresh ingredients, dairy components, or other perishable elements typically require “use by” dates that clearly communicate safety rather than quality implications. Using “best before” dates inappropriately can expose businesses to liability if consumers become ill from consuming expired products.

Date formatting errors may seem minor but can trigger compliance violations and consumer confusion. Australian regulations specify exact formatting requirements for different date ranges, and failure to follow these formats precisely can result in non-compliant labels requiring correction.

Failure to link date marking with appropriate storage instructions represents another common oversight. Date marking accuracy depends on proper storage conditions, and labels that specify dates without corresponding storage requirements fail to provide consumers with information necessary to achieve the promised shelf life.

Supplier information omissions often result from businesses’ failure to understand exactly whose information must appear on labels. The requirement isn’t necessarily for manufacturer information—it’s for the business responsible for the food in Australia, which may be an importer, distributor, or brand owner rather than the actual producer.

Address incompleteness frequently creates compliance issues, particularly when businesses use post office boxes or insufficient address detail that doesn’t meet regulatory requirements for consumer contact and regulatory correspondence. The address must enable both consumers and regulators to establish meaningful contact with responsible parties.

Font size and legibility issues persist despite clear regulatory guidance, often because businesses prioritize design aesthetics over practical readability. Minimum font size requirements exist for consumer protection, and labels that technically meet size requirements may still fail practical legibility standards.

Decorative fonts present particular challenges when used for regulatory information like nutrition panels or ingredient lists. While decorative fonts can enhance brand personality, they often compromise readability at small sizes where regulatory information must appear. The most effective approach reserves decorative fonts for brand elements while using highly legible fonts for compliance-critical information.

Insufficient contrast between text and background colors can render otherwise compliant labels illegible in real-world shopping environments. High contrast requirements exist for accessibility reasons, and labels that appear readable in ideal design environments may fail to serve consumers effectively under typical retail lighting conditions.

The Top 10 Australian food labeling mistakes provides legal perspective on the most serious compliance failures, while Regulatory compliance mistakes in packaging offers industry insights into systematic prevention strategies.

Label update failures represent ongoing operational challenges that can transform initially compliant labels into non-compliant problems over time. Recipe changes, regulatory updates, supplier modifications, and market expansion all require corresponding label updates that businesses often overlook or delay inappropriately.

Establishing systematic review processes helps prevent these operational oversights by creating regular checkpoints for label accuracy verification. Effective systems include quarterly compliance reviews, supplier change notification procedures, and regulatory monitoring that ensures timely awareness of requirement changes.

Avoiding these pitfalls becomes much easier when you partner with a knowledgeable label supplier who understands Australian requirements and can deliver quickly when you need updates.

Your choice of label supplier represents one of the most strategic decisions you’ll make for your Australian food business—a partnership that can either streamline your path to compliance success or create ongoing obstacles that impede growth and increase risk. The right supplier becomes an extension of your team, providing expertise, speed, and reliability that transforms labeling from a compliance burden into a competitive advantage. Understanding what separates exceptional suppliers from merely adequate ones can save you countless headaches and potentially catastrophic mistakes.

Australian regulatory expertise stands as the foundational requirement that separates qualified food label suppliers from general printing companies. The complexity and specificity of FSANZ requirements, combined with the rapid pace of regulatory changes like the February 2024 PEAL implementation and forthcoming 2026 Health Star Rating mandates, demand suppliers who live and breathe Australian food law rather than just print attractive labels.

Look for suppliers who can discuss recent regulatory changes knowledgeably and provide specific guidance on emerging requirements. A qualified supplier should understand not just current regulations but also implementation timelines, transition periods, and practical compliance strategies that help you navigate changes efficiently. When evaluating potential partners, ask specific questions about allergen declaration requirements, country of origin calculations, or nutrition panel formatting—their responses will quickly reveal depth of expertise.

Regulatory knowledge extends beyond mere awareness to practical application guidance. The best suppliers help you understand not just what regulations require but how to implement those requirements effectively within your specific business context. This includes guidance on material selection for regulatory compliance, design approaches that balance aesthetics with legal requirements, and strategies for maintaining compliance across product lines and market expansions.

Speed and flexibility advantages become increasingly critical in today’s fast-moving food industry, where delayed product launches, missed promotional opportunities, or slow responses to regulatory changes can cost significant revenue and competitive positioning. The ability to obtain high-quality, compliant labels quickly can mean the difference between capturing market opportunities and watching competitors succeed while you wait for labels.

Rapid prototyping capabilities allow you to test design concepts and receive actual label samples quickly, enabling informed decision-making without extended delays. This becomes particularly valuable when developing new products, entering new markets, or responding to competitive pressures that require quick pivots or product modifications.

Quick turnaround for regulatory updates provides essential agility when compliance requirements change or when you discover labeling issues that require immediate correction. The difference between suppliers who can provide corrected labels within days versus weeks can determine whether regulatory issues remain minor inconveniences or escalate into major business disruptions requiring product recalls or market delays.

Emergency reprinting capabilities offer crucial insurance against unforeseen circumstances—equipment failures, supply chain disruptions, or sudden volume increases that exhaust label inventory. Suppliers who can respond quickly to urgent requests help ensure your business continuity even when unexpected challenges arise.

Quality assurance standards protect your investment and brand reputation by ensuring every label meets both technical specifications and aesthetic standards. Professional suppliers implement systematic quality control processes that verify color accuracy, adhesive performance, durability characteristics, and print quality before delivery.

Color matching capabilities ensure brand consistency across print runs and over time, preventing the gradual color drift that can undermine brand recognition and professional appearance. Consistent colors become particularly important for businesses with multiple products or frequent reprinting requirements where color variations between different label batches create unprofessional appearance and consumer confusion.

Adhesive testing verifies that label materials and adhesives perform appropriately under anticipated storage and usage conditions. Professional suppliers understand the performance characteristics of different adhesive systems and can recommend optimal solutions for specific applications, from freezer environments to high-humidity conditions to oil-resistant requirements.

Durability verification ensures labels maintain legibility and attachment throughout anticipated product lifecycles. This includes testing for temperature cycling, moisture exposure, mechanical stress, and UV exposure that could degrade label performance and compromise compliance or brand presentation.

Food safety certifications demonstrate supplier commitment to appropriate handling and material selection for food contact applications. Look for suppliers who understand and implement food-safe printing processes, use appropriate inks and adhesives, and maintain clean production environments suitable for food packaging applications.

Technical support services transform suppliers from mere vendors into strategic partners who contribute expertise and guidance that enhances your business capabilities. The best suppliers provide design assistance that helps optimize label layouts for both regulatory compliance and brand effectiveness, material recommendations based on specific product requirements and environmental conditions, and compliance review services that catch potential issues before they become expensive problems.

Design assistance becomes particularly valuable for businesses without internal graphic design expertise or for complex products requiring sophisticated regulatory information presentation. Experienced suppliers understand how to balance mandatory information requirements with brand appeal, creating labels that satisfy both legal compliance and marketing objectives.

Material recommendations based on deep technical knowledge help you avoid costly mistakes in material selection while optimizing performance and cost-effectiveness. Suppliers who understand the relationship between product characteristics, storage conditions, and label material properties can guide you toward optimal solutions that perform reliably while controlling costs.

Compliance review services provide expert evaluation of label designs and content before production, catching potential regulatory issues during the design phase when corrections are inexpensive rather than after production when mistakes become costly. This service becomes particularly valuable when launching new products, expanding into new markets, or navigating complex regulatory requirements.

Scalability considerations ensure your supplier partnership can grow with your business, from initial small-batch requirements through potential high-volume production needs. Suppliers who can handle both artisan-scale runs and commercial production volumes provide consistency and relationship continuity as your business evolves.

Handling small artisan runs efficiently demonstrates supplier flexibility and willingness to support growing businesses during their early stages. Many commercial printers focus exclusively on high-volume orders, leaving smaller businesses with limited options or suboptimal service levels.

Large commercial production capabilities become essential as businesses grow and require higher volumes, faster turnaround times, and more sophisticated logistics support. Suppliers who can scale services appropriately help ensure smooth business growth without requiring disruptive vendor changes.

Local advantages offer practical and strategic benefits that international or distant suppliers cannot match. Understanding Australian supply chains helps suppliers provide realistic delivery timeframes, responsive service, and efficient logistics that minimize inventory requirements and enable more agile business operations.

Faster delivery capabilities reduce inventory carrying costs while enabling more responsive product development and market introduction cycles. Local suppliers often provide same-day or next-day delivery options that can prove crucial during critical business situations or promotional deadlines.

Personal service relationships enable more nuanced communication, better problem-solving, and collaborative approaches that enhance business outcomes. Working with suppliers who understand your business context and maintain ongoing relationships often produces better results than transactional relationships with distant vendors.

When evaluating potential suppliers, consider faststickers.com.au as an example of Australian expertise combined with rapid delivery capabilities. Their specialization in food-grade label stickers, understanding of local regulatory requirements, and commitment to fast turnaround times exemplify the type of supplier partnership that can accelerate business success while ensuring compliance reliability.

Cost considerations require balancing quality, speed, and budget constraints while avoiding the false economy of cheap labels that compromise compliance or performance. The lowest-cost option often proves expensive when labels fail, require reprinting, or create compliance issues that trigger regulatory action.

Quality investments in appropriate materials, reliable adhesives, and professional printing typically justify higher initial costs through better performance, enhanced brand presentation, and reduced risk of expensive failures. Consider total cost of ownership rather than just initial purchase price when evaluating supplier options.

Speed premiums for urgent delivery or rapid turnaround often provide excellent value when they enable market opportunities, prevent stock-outs, or resolve compliance issues quickly. The cost of rush services typically proves minimal compared to the cost of missed opportunities or extended business disruptions.

Supplier evaluation frameworks help systematize decision-making by establishing clear criteria for supplier assessment and ongoing performance monitoring. Consider regulatory knowledge depth, quality control processes, delivery reliability, technical support capabilities, scalability potential, and cost competitiveness as key evaluation dimensions.

Reference checking with other food businesses provides valuable insights into supplier performance under real-world conditions. Ask specific questions about delivery reliability, quality consistency, problem resolution, and overall business relationship satisfaction.

The FSANZ consultation on nutrition labeling demonstrates the ongoing evolution of regulatory requirements, reinforcing the importance of suppliers who stay current with regulatory changes and can adapt quickly to new requirements.

With the right knowledge, materials, and supplier partnership in place, you’re ready to create food labels that protect your business and enhance your brand.

Navigating the complex landscape of Australian food labeling requirements need not be a source of constant anxiety or business risk. As we’ve explored throughout this comprehensive guide, success lies in understanding that proper food labeling represents far more than regulatory compliance—it’s a strategic business capability that protects your company from devastating fines and recalls while building the consumer trust essential for long-term growth.

The stakes have never been higher. With 51% of food recalls in 2023 attributed to allergen labeling failures and corporate fines reaching $550,000 for serious violations, the cost of labeling mistakes can quickly overwhelm even successful businesses. Yet the businesses that master compliant labeling gain significant competitive advantages: smoother retail approval processes, enhanced consumer confidence, and protection from the regulatory and reputational disasters that destroy unprepared competitors.

The regulatory environment will continue evolving, with mandatory Health Star Rating requirements expected by 2026 and ongoing refinements to allergen labeling, nutrition panels, and country of origin requirements. Rather than viewing these changes as obstacles, forward-thinking businesses can leverage superior labeling capabilities to differentiate themselves in increasingly competitive markets.

The investment in professional, compliant food label stickers pays dividends far beyond avoiding penalties. Quality labels enhance perceived product value, facilitate retail acceptance, and demonstrate the professional attention to detail that modern consumers expect and demand. In contrast, poor labeling—whether non-compliant, illegible, or unprofessional in appearance—immediately undermines consumer confidence and retailer relationships that may take years to rebuild.

Perhaps most importantly, proper labeling protects the consumers who trust your products and depend on accurate information to make safe, informed choices. Every properly declared allergen, clearly presented nutrition panel, and accurate ingredient list represents your commitment to consumer welfare and business integrity.

The complexity of achieving consistently excellent labeling results demands strategic partnerships with suppliers who understand both current requirements and emerging trends. Attempting to navigate this complexity without expert support often proves more expensive and risky than investing in professional guidance from the outset.

Success requires systematic approaches that integrate regulatory knowledge, appropriate materials, professional design, and reliable execution. The businesses that treat labeling as a strategic capability rather than an administrative burden consistently outperform competitors who view compliance as merely a cost of doing business.

The path to labeling excellence starts with a single decision: partnering with Australian labeling experts who understand your challenges and can deliver the fast, compliant solutions your business demands. At faststickers.com.au, we specialize in transforming complex regulatory requirements into straightforward business solutions, delivering food-grade label stickers that meet all FSANZ standards while enhancing your brand presentation.

Our Australian team doesn’t just print labels—we provide strategic labeling guidance that protects your business from costly compliance failures while accelerating your path to market success. Whether you need freezer-grade materials for frozen products, oil-resistant labels for prepared foods, or premium materials that justify luxury pricing, we match optimal solutions to your specific requirements with the speed your business demands.

Don’t let labeling complexity slow your growth or expose your business to unnecessary risks. Contact faststickers.com.au today for expert consultation on your food labeling needs. We’ll help you choose the perfect materials, ensure complete regulatory compliance, and deliver professional results with the lightning-fast turnaround times that keep successful Australian food businesses moving forward.

Your products deserve labels as exceptional as their contents. Let’s create them together.

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

The Complete Guide to Candle Labels: Design, Materials & Australian Compliance Australia’s candle market is experiencing unprecedented growth, with handcrafted and artisanal candles driving a $200+

The Aussie Choice for a Greener Tomorrow Eco-friendly stickers are no longer a niche choice—they’re quickly becoming the go-to for Aussie businesses and event organisers

Choosing the Perfect Sticker Type for Your Project: A Quick Guide Picking the right sticker can make or break your project. Many get stuck choosing

Harnessing Gippsland’s Printing Expertise for Australian Business Success Most Australian businesses settle for slow, generic printing from big companies. You don’t have to. Gippsland printing