QR Code Stickers Australia

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

Transform your laptop from ordinary to extraordinary with custom laptop stickers that reflect your personality, brand, or interests. In Australia’s competitive digital landscape, personalizing your tech has become more than just aesthetics—it’s about making a statement. Whether you’re a student wanting to stand out on campus, a professional looking to brand your business laptop, or simply someone who loves creative expression, laptop stickers offer an affordable and removable way to customize your device.

This comprehensive guide explores everything you need to know about laptop stickers in Australia, from choosing the right materials and designs to professional application techniques that ensure your decals look flawless and last for years. We’ll cover the latest trends, practical tips, and insider secrets from Australia’s leading sticker specialists, backed by industry data showing that the personalized stickers market is valued at USD 4.84 billion in 2025 and continues growing rapidly.

Laptop stickers have evolved far beyond simple decoration to become powerful tools for self-expression, brand communication, and cultural identity. In essence, laptop stickers are adhesive graphics designed specifically for application on laptop surfaces, distinct from laptop skins (which cover larger areas) or screen protectors (which serve purely functional purposes). These versatile decals range from tiny logo badges to elaborate artistic designs that transform your device into a canvas of personal meaning.

The surge in laptop personalization across Australia reflects broader cultural shifts toward individual expression and digital identity curation. Recent industry research shows that laptop stickers are especially popular with Gen Z and Millennial audiences, who view their devices as extensions of their personality rather than mere tools. This demographic drives the growing demand for customization options that allow them to showcase their interests, affiliations, and aesthetic preferences.

Australian laptop sticker culture draws heavily from the country’s unique identity markers. Popular themes include surf culture imagery, native wildlife like kangaroos and koalas, sports team logos (particularly AFL and NRL), university emblems, and tech company badges. The rise of remote work and digital nomad lifestyles has further amplified this trend, with professionals using branded laptop stickers to maintain company identity while working from cafes, co-working spaces, and flexible office environments.

Beyond personal expression, laptop stickers serve several practical benefits that contribute to their widespread adoption. They provide a protective layer against minor scratches and scuffs, helping preserve your laptop’s resale value. More importantly, they make device identification effortless in shared spaces—a crucial advantage in university libraries, office hot-desking environments, or conference settings where identical laptops abound. Many users report that distinctive sticker collections become conversation starters, facilitating networking opportunities and social connections.

The economic appeal of laptop stickers cannot be understated. While laptop cases can cost $50-200 and new devices require significant investment, quality stickers typically range from $5-50, making personalization accessible across all income levels. This affordability democratizes customization, allowing students, professionals, and creative individuals to refresh their laptop’s appearance regularly without financial strain.

The psychological impact of laptop personalization extends deeper than surface aesthetics. Research in environmental psychology suggests that personalizing our daily tools and spaces enhances feelings of ownership, control, and emotional connection. For many Australians, particularly those spending 8+ hours daily with their laptops, this emotional bonding improves overall satisfaction and productivity.

Current trends reflect Australia’s diverse cultural landscape and technological sophistication. Minimalist designs featuring clean typography and geometric patterns appeal to professionals seeking subtle personalization. Conversely, maximalist approaches combine multiple stickers to create collages representing complex interests and affiliations. The rise of small business entrepreneurship has also driven demand for custom business logo stickers, with many Australian startups and freelancers using laptop branding as mobile advertising.

Climate considerations play a significant role in Australian sticker selection, with consumers increasingly prioritizing UV-resistant and weatherproof materials that withstand the country’s intense sunlight and varied weather conditions. This practical requirement has shaped local preferences toward high-quality vinyl and specialty materials that maintain their appearance despite environmental challenges.

Understanding these foundational elements of laptop sticker culture in Australia sets the stage for exploring the technical specifications and material options that determine performance and longevity.

Selecting the right material for your laptop stickers determines their durability, appearance, and performance across Australia’s diverse climate conditions. Understanding material properties empowers you to make informed decisions that balance aesthetic preferences with practical requirements, ensuring your investment delivers long-term satisfaction.

Vinyl stickers represent the gold standard for laptop applications, offering exceptional versatility and performance characteristics that make them ideal for Australian conditions. High-quality vinyl materials are waterproof, weather-resistant, and durable on both flat and curved surfaces, making them perfect for laptop lids that experience daily handling and environmental exposure. Premium vinyl formulations feature UV-resistant properties that prevent fading even under Australia’s intense sunlight, maintaining color vibrancy for years rather than months.

The flexibility of vinyl allows seamless application around laptop curves and corners without cracking or lifting. This adaptability proves crucial for modern laptop designs featuring rounded edges and complex surface geometries. Professional-grade vinyl stickers can withstand temperature fluctuations from air-conditioned offices to outdoor work sessions, maintaining their adhesive bond regardless of environmental changes.

Color reproduction in vinyl stickers achieves remarkable accuracy and saturation, particularly important for brand logos and artistic designs where color fidelity matters. The material accepts various printing technologies, from digital inkjet to screen printing, enabling both photographic detail and solid color brilliance. Matte finishes reduce glare and fingerprint visibility, while gloss finishes enhance color pop and provide easier cleaning.

Clear stickers offer subtle sophistication for users preferring understated personalization or professional branding requirements. These transparent decals create sophisticated layering effects, allowing laptop’s original finish to show through while adding protective coverage and design elements. Clear materials excel in corporate environments where bold graphics might appear unprofessional, providing brand presence without visual dominance.

Polyester-based clear stickers demonstrate superior clarity and scratch resistance compared to vinyl alternatives. Polyester materials offer exceptional durability and UV resistance, making them ideal for long-term applications on expensive laptops. The material’s chemical resistance protects against spills and cleaning products commonly encountered in office environments.

Clear stickers enable creative layering techniques, allowing designers to build complex visual effects through transparency overlaps. This capability particularly appeals to graphic designers, photographers, and creative professionals who appreciate subtle complexity in their laptop aesthetics. Window cling variants provide repositionable options for temporary branding or seasonal customization.

Die-cut stickers represent premium customization through precise cutting technology that creates exact shapes matching logos, artwork, or custom designs. Unlike rectangular stickers with excess border material, die-cutting eliminates background, producing clean edges that follow design contours exactly. This precision creates professional appearance suitable for business branding and high-end personal customization.

The die-cutting process accommodates virtually any shape complexity, from simple circles to intricate artwork with fine details and cut-outs. This flexibility enables faithful reproduction of existing logos and designs without compromise, maintaining brand consistency across different applications. Premium die-cut stickers often feature kiss-cutting techniques that precisely cut the sticker material while leaving the backing paper intact, facilitating easy application and positioning.

Material finish options significantly impact both appearance and performance. Matte finishes reduce reflection and provide sophisticated, non-glossy appearance that complements modern laptop designs. They resist fingerprints and show less wear from handling, making them ideal for frequently-touched areas. Gloss finishes enhance color vibrancy and provide easier cleaning but may show fingerprints more readily. Satin finishes balance these characteristics, offering moderate sheen with practical maintenance properties.

Specialty finishes expand creative possibilities beyond traditional options. Metallic finishes incorporating silver, gold, or copper create premium appearance suitable for luxury branding or artistic applications. Holographic materials produce rainbow effects that shift with viewing angle, popular among younger demographics and creative professionals. Textured finishes including linen, canvas, and leather effects add tactile dimension to laptop customization.

Adhesive selection critically impacts long-term performance and removal characteristics. Permanent adhesives create strong bonds suitable for long-term applications but may leave residue upon removal. Removable adhesives allow clean removal without residue, ideal for temporary applications, rental laptops, or users who frequently change designs. Repositionable adhesives enable multiple placement attempts during application, reducing waste and installation stress.

Australian climate considerations significantly influence material selection. The country’s high UV exposure demands materials with proven UV stability to prevent premature fading and degradation. Temperature cycling between air-conditioned interiors and outdoor heat requires adhesives that maintain bond strength across wide temperature ranges. Humidity variations, particularly in tropical northern regions, necessitate materials resistant to moisture-induced adhesive failure.

Understanding these material characteristics enables informed decision-making that aligns with your specific requirements, aesthetic preferences, and performance expectations. This technical foundation naturally leads into the creative process of designing custom laptop decals that effectively utilize these material properties.

Creating effective laptop stickers requires balancing artistic vision with technical constraints, ensuring your design not only looks stunning but also performs optimally across different materials and application conditions. The design process encompasses conceptual development, technical execution, and practical considerations that determine both immediate impact and long-term satisfaction.

Design principles for laptop applications differ significantly from traditional print media due to scale limitations, viewing distances, and functional constraints. The relatively small canvas of most laptop lids demands exceptional clarity and impact, requiring designers to prioritize essential elements while eliminating unnecessary complexity. Effective laptop sticker designs follow the principle of scalable simplicity—they remain legible and impactful whether viewed from arm’s length during use or across a room during presentations.

Color theory becomes particularly crucial in laptop sticker design, where contrast against various laptop finishes ensures visibility across different backgrounds. Light-colored designs may disappear against silver laptops, while dark graphics can blend with black devices. Professional designers often create multiple color variants or incorporate contrasting outlines to ensure visibility across diverse laptop finishes. The trending design styles for 2025 include retro-inspired aesthetics, holographic effects, and Kawaii (cute) elements that resonate with younger demographics, while geometric patterns and minimalist approaches appeal to professional users.

Size and placement considerations significantly impact both visual effectiveness and practical functionality. Laptop lid dimensions vary considerably across brands and models, requiring designers to consider proportion relationships and placement options that avoid interference with hinges, vents, and essential hardware elements. The golden ratio often guides effective proportions, creating harmonious relationships between sticker size and laptop dimensions.

Strategic placement enhances both aesthetics and functionality. Center-positioned stickers create formal, balanced appearance suitable for business applications, while off-center or corner placements enable dynamic, casual aesthetics. Multiple sticker arrangements require careful spacing and visual flow consideration, ensuring individual elements complement rather than compete with each other. Designers must also consider the laptop’s open position, ensuring sticker placement doesn’t interfere with typing comfort or screen visibility.

File requirements and technical specifications determine print quality and production feasibility. Professional laptop sticker production requires vector graphics or high-resolution raster images at 300 DPI minimum to ensure crisp reproduction at actual size. Vector formats (AI, EPS, PDF) provide scalability advantages, maintaining quality across different size requirements and enabling easy modification during the design process.

Color mode selection impacts final reproduction quality significantly. CMYK color mode aligns with professional printing processes, while RGB files may produce unexpected color shifts during production. Spot color systems like Pantone provide precise color matching for brand-critical applications, particularly important for corporate logos and brand consistency requirements. Understanding color gamut limitations helps designers make informed decisions about achievable color reproduction within material constraints.

Custom design services versus DIY creation presents important trade-offs between cost, time, and quality outcomes. Professional design services bring expertise in technical requirements, brand consistency, and visual impact optimization. They understand material limitations, production constraints, and application considerations that amateur designers often overlook. Working with experienced designers involves collaborative revision processes, ensuring final designs meet both aesthetic goals and technical requirements.

When engaging professional design services, clear communication about intended use, target audience, and performance requirements guides effective collaboration. Providing reference materials, brand guidelines, and usage context helps designers create solutions that align with your vision while optimizing for laptop sticker applications. Revision cycles allow refinement and optimization, ensuring satisfaction before production investment.

Copyright and licensing considerations become critical when incorporating existing artwork, fonts, or imagery into laptop sticker designs. Using copyrighted logos, images, or fonts without permission creates legal liability and may result in production delays or refusal by professional printing services. Original artwork provides complete creative control and eliminates licensing concerns, making it the preferred approach for unique customization.

Font licensing deserves particular attention, as many commercial fonts require licensing for use in printed materials like stickers. Free and open-source fonts provide safer alternatives, though designers should verify specific licensing terms. Custom hand-lettering eliminates licensing concerns while creating distinctive, personalized aesthetics that stand apart from typical typography.

Brand integration strategies depend on intended use and organizational requirements. Personal branding might incorporate social media handles, personal logos, or contact information in subtle, tasteful presentations. Business applications require adherence to brand guidelines, ensuring consistency with other marketing materials and corporate identity standards. Color palettes, typography choices, and imagery style should align with established brand personality and positioning.

Current design trends reflect broader cultural shifts and technological capabilities. Minimalist approaches emphasizing clean typography and simple geometric shapes appeal to professionals seeking sophisticated customization. Hand-lettered quotes and motivational phrases resonate with creative professionals and students. Retro aesthetics drawing from 80s and 90s design sensibilities create nostalgic appeal across multiple demographics.

Geometric patterns and mathematical designs appeal to tech professionals and engineers, while organic, nature-inspired elements connect with environmentally conscious users. Australian-specific imagery including native wildlife, landscape silhouettes, and cultural symbols creates local relevance and pride. Abstract patterns and artistic interpretations provide unique personalization without specific meaning constraints.

Collaboration between personal vision and technical requirements ensures successful outcomes that balance creative expression with practical performance. Understanding material capabilities, application methods, and durability expectations guides design decisions that optimize both immediate impact and long-term satisfaction. This foundation prepares for the critical application phase, where proper technique ensures professional-quality results.

Proper application technique separates amateur results from professional-quality installations that maintain their appearance and performance for years. Understanding surface preparation, application methodology, and troubleshooting techniques ensures your laptop stickers achieve their full aesthetic and protective potential while avoiding common pitfalls that compromise appearance and longevity.

Surface preparation establishes the foundation for successful application and long-term adhesive performance. Laptop surfaces accumulate oils from handling, dust from environmental exposure, and residues from manufacturing processes, all of which interfere with optimal adhesive bonding. Professional application requires thorough cleaning with isopropyl alcohol to remove these contaminants and create ideal bonding conditions.

Begin preparation by powering down the laptop completely and removing it from any charging connections. This safety measure prevents electrical issues and allows thorough cleaning of the target surface. Use 70% isopropyl alcohol applied to a clean, lint-free microfiber cloth rather than spraying directly onto the laptop surface. Direct spraying risks liquid penetration into ports, vents, or seams that could damage internal components.

Clean the entire application area systematically, working from one edge to the other with overlapping strokes. Pay particular attention to areas that receive frequent hand contact, as skin oils create invisible barriers that prevent proper adhesive contact. Allow the alcohol to evaporate completely—typically 2-3 minutes in normal room conditions—before proceeding with application. Rushing this drying phase traps moisture beneath the sticker, potentially causing adhesive failure or bubble formation.

Temperature conditions significantly impact application success and long-term performance. Optimal application occurs at room temperature (68-75°F/20-24°C) with moderate humidity levels. Cold conditions make sticker materials rigid and difficult to conform to surface contours, while excessive heat can cause premature adhesive activation during positioning. Australian users should avoid outdoor application during extreme weather, opting for climate-controlled indoor environments whenever possible.

Essential tools for professional application include a squeegee or smoothing tool, precision ruler or measuring tape, and high-quality masking tape for positioning assistance. Plastic squeegees work effectively for most applications, while felt-edged tools provide gentler pressure for delicate finishes. Avoid using credit cards or improvised tools that may scratch laptop surfaces or tear sticker materials.

Step-by-step application methodology ensures consistent, professional results regardless of sticker size or complexity. Begin by positioning the sticker without removing any backing material, using this dry-fit process to confirm exact placement and make necessary adjustments. Mark positioning reference points with small pieces of masking tape, creating guides that ensure accurate final placement.

The hinge method provides optimal control for larger stickers and complex designs. Position the sticker in its final location and secure one edge with masking tape, creating a hinge that allows the sticker to fold back while maintaining perfect alignment. Remove approximately half of the backing paper, exposing the adhesive for the first section.

Professional squeegee technique involves tilting the tool at approximately 30 degrees and applying firm, consistent pressure while moving in straight, overlapping strokes. Start from the hinge edge and work toward the opposite side, maintaining steady pressure and overlapping each stroke by roughly 25%. This systematic approach eliminates air pockets and ensures complete adhesive contact across the entire surface.

Bubble prevention requires understanding both the causes and prevention techniques that professional installers employ. Air bubbles typically result from uneven pressure application, contaminated surfaces, or premature backing removal that allows air entrapment. The wet application method provides additional control for challenging installations, particularly useful for large stickers or complex curved applications.

Create a light soap solution using a few drops of dish detergent in a spray bottle filled with clean water. This mixture reduces initial adhesive tack, allowing repositioning and air removal during the application process. Apply the solution lightly to both the cleaned laptop surface and the exposed adhesive, then position the sticker and work out air bubbles using gradual pressure from the center outward.

The wet method requires patience as the soap solution gradually evaporates and the adhesive reaches full strength over 24-48 hours. During this curing period, avoid exposing the laptop to extreme temperatures or excessive handling that could compromise the developing bond.

Common mistakes that compromise installation quality include rushing the process, inadequate surface preparation, and incorrect pressure application. Attempting to work too quickly often results in misalignment, bubble entrapment, or material stretching that creates permanent distortion. Taking time for careful preparation and methodical application yields dramatically better results than hurried attempts.

Incorrect pressure distribution represents another frequent error. Excessive pressure can stretch vinyl materials beyond their recovery limits, while insufficient pressure fails to establish proper adhesive contact. Professional installers maintain consistent, moderate pressure throughout the process, allowing the material and adhesive to perform as designed.

Temperature-related mistakes occur when users attempt application in non-optimal conditions. Cold weather makes materials brittle and difficult to work with, while excessive heat can cause adhesive flow that complicates positioning. Australian users should particularly avoid application during extreme heat events or in direct sunlight that overheats laptop surfaces.

Advanced techniques for complex applications address challenges posed by curved surfaces, multiple sticker combinations, and precision alignments. Relief cuts allow materials to conform to curves without bunching or stretching, particularly useful for laptop corners and rounded edges. These small cuts should extend only into the material backing, not through the adhesive layer.

Working with multiple stickers requires careful spacing and alignment consideration. Professional installers often use temporary gridlines created with removable masking tape to ensure consistent spacing and parallel alignment across multiple elements. This preparation method prevents cumulative errors that become obvious once the full arrangement is complete.

Transfer tape applications enable precise positioning of complex or small stickers that would be difficult to handle directly. The transfer tape maintains sticker position during backing removal and initial positioning, then peels away cleanly once the sticker is properly placed.

Quality verification involves systematic inspection for potential issues before considering the installation complete. Check for lifted edges, trapped air bubbles, and proper adhesive contact around the entire perimeter. Small air bubbles can often be eliminated using gentle pressure and working toward the nearest edge. Persistent bubbles may require careful puncturing with a fine needle, followed by pressure to expel trapped air.

Proper application technique sets the foundation for long-term satisfaction and performance, leading naturally into maintenance practices that preserve your investment and extend sticker lifespan across Australia’s challenging environmental conditions.

Proper maintenance practices significantly extend laptop sticker lifespan while preserving their appearance and protective qualities throughout their service life. Understanding daily care requirements, appropriate cleaning methods, and environmental protection strategies ensures your investment continues delivering value across years rather than months, particularly important given Australia’s challenging climate conditions.

Daily care practices form the foundation of effective sticker maintenance, requiring minimal effort while preventing cumulative damage that shortens sticker lifespan. Gentle handling during laptop transport and use protects sticker edges from lifting and peeling, the most common failure modes for laptop applications. Avoid dragging laptops across surfaces or stacking items on closed lids, both of which can catch sticker edges and initiate failure.

Consistent laptop bag or sleeve usage provides crucial protection against abrasive contact, UV exposure, and temperature extremes that gradually degrade sticker materials and adhesive bonds. Quality laptop bags feature padded compartments that prevent shifting and rubbing during transport, while weather-resistant materials shield against moisture and temperature fluctuations. This protection becomes particularly important for Australian users who frequently transition between air-conditioned indoor environments and harsh outdoor conditions.

Temperature management strategies protect both laptop functionality and sticker integrity. Avoid leaving laptops in vehicles during extreme weather, as temperature spikes can soften adhesives and cause sticker failure. Australian heat conditions can be particularly challenging, with interior vehicle temperatures often exceeding 60°C (140°F) during summer months, well beyond the thermal limits of most adhesive systems.

Cleaning methodologies must balance sticker preservation with hygiene requirements, particularly important given increased awareness of device cleanliness. Gentle cleaning products and techniques prevent damage while maintaining professional appearance and sanitary conditions. Harsh chemicals, abrasive materials, and excessive moisture can compromise sticker materials and adhesive bonds, necessitating careful product selection and application methods.

Water-based cleaning solutions using mild dish detergent provide effective cleaning without material damage. Mix a small amount of gentle dish soap with warm water to create a light cleaning solution. Apply using a barely damp microfiber cloth, working in gentle circular motions across sticker surfaces. This method removes fingerprints, dust, and surface contamination without saturating materials or compromising adhesive bonds.

Isopropyl alcohol solutions (70% concentration) effectively disinfect surfaces while evaporating quickly to prevent moisture damage. Apply alcohol to the cleaning cloth rather than directly onto stickers, maintaining control over moisture levels and preventing liquid penetration around sticker edges. Allow complete evaporation before closing laptop lids or placing devices in bags, typically requiring 1-2 minutes in normal conditions.

Avoid ammonia-based cleaners, acetone, or other strong solvents that can dissolve vinyl materials or weaken adhesive bonds. These products may appear to clean effectively initially but often cause delayed damage that manifests as color fading, material brittleness, or adhesive failure. Similarly, avoid abrasive materials like paper towels or rough cloths that can scratch sticker surfaces or catch on edges.

Protecting edges represents a critical maintenance focus, as edge lifting typically initiates complete sticker failure. Regular inspection for lifted corners or edges enables early intervention before problems become irreversible. Gently press down any slightly lifted areas using clean fingers, ensuring the adhesive reconnects with the laptop surface. More significant lifting may require careful cleaning of the affected area and adhesive reactivation using gentle heat.

Environmental humidity management becomes particularly important in tropical Australian regions where high humidity can soften adhesives and promote edge lifting. Silica gel packets placed in laptop bags help control moisture levels during storage and transport, particularly beneficial for users in Queensland and northern regions experiencing high humidity seasons.

Wear indicators help determine appropriate replacement timing before sticker condition becomes unsightly or non-functional. Color fading represents an early indicator, typically beginning around sticker edges where UV exposure is most concentrated. While some fading may be acceptable depending on aesthetic requirements, significant color shift or complete bleaching indicates material degradation that will continue accelerating.

Edge lifting or curling indicates adhesive failure that typically cannot be reversed through maintenance alone. Small areas of lifting may be temporarily addressed, but progressive failure usually requires complete replacement to maintain professional appearance. Attempting to over-extend sticker lifespan often results in residue problems and surface damage that complicates replacement applications.

Surface cracking or material brittleness indicates UV degradation that compromises both appearance and protective function. This deterioration typically occurs after 2-3 years of outdoor exposure in Australian conditions, though high-quality materials with UV inhibitors may last significantly longer. Cracked materials become increasingly fragile and may leave removal residue when replacement becomes necessary.

Climate-specific considerations for Australian conditions address unique environmental challenges that affect sticker performance and longevity. The country’s high UV exposure necessitates materials specifically rated for outdoor durability, even for indoor laptop applications that experience occasional outdoor use. Standard indoor-rated materials may fail prematurely when exposed to Australian sunlight levels.

Seasonal maintenance adjustments account for varying environmental stress levels throughout the year. Summer months require increased attention to heat protection and UV exposure, while winter conditions may necessitate humidity control in some regions. Regional variations require localized strategies—users in Darwin face different challenges than those in Melbourne or Perth.

Air conditioning cycles create temperature and humidity fluctuations that stress adhesive bonds over time. Gradual transitions between environments minimize this stress, allowing materials to accommodate changes without sudden expansion or contraction that can cause failure. Avoid rapid temperature changes when possible, such as moving directly from air-conditioned vehicles to hot outdoor conditions.

Professional maintenance services may be appropriate for high-value or business-critical applications where appearance consistency is essential. Some specialized service providers offer cleaning, edge repair, and protective coating services that extend sticker lifespan beyond typical expectations. These services typically prove cost-effective for business applications where laptop appearance affects professional image.

Warranty considerations vary among suppliers and materials, with some high-end products offering performance guarantees against fading, lifting, or material failure under specified conditions. Understanding warranty terms and documentation requirements ensures eligibility for replacement or refund should premature failure occur. Quality suppliers often stand behind their materials with guarantees that reflect confidence in performance expectations.

Regular maintenance creates the foundation for long-term satisfaction with laptop sticker investments, while understanding care requirements naturally leads into commercial applications where professional image and consistency assume even greater importance for business success and brand representation.

Laptop stickers represent powerful, cost-effective marketing tools that extend brand visibility far beyond traditional advertising boundaries, creating mobile brand ambassadors that generate consistent exposure across diverse professional and social environments. Understanding strategic applications, design requirements, and measurement methodologies enables businesses to leverage laptop customization for significant marketing return on investment.

Mobile branding opportunities through laptop stickers create unique advantages unavailable through traditional advertising channels. Unlike stationary signage or time-limited digital ads, branded laptops accompany employees and stakeholders throughout their daily activities, generating consistent brand impressions across various environments and audiences. This mobility proves particularly valuable for service-based businesses where face-to-face client interactions represent primary customer touchpoints.

Conference and trade show environments exemplify laptop sticker effectiveness, where branded devices visible during presentations, networking sessions, and exhibition displays reinforce brand presence without additional marketing investment. Research demonstrates that promotional products generate 500% more customer referrals than other advertising forms, with laptop stickers offering exceptional visibility duration compared to traditional promotional items that may be quickly discarded or forgotten.

Professional meeting contexts benefit significantly from subtle laptop branding that maintains brand awareness without appearing overly promotional. Well-designed stickers communicate professionalism and attention to detail while providing conversation starters that facilitate business development opportunities. This approach proves particularly effective for consultants, freelancers, and small business owners who rely on personal brand recognition for client acquisition.

Employee branding initiatives create unified visual identity across distributed teams while fostering organizational pride and cohesion. Coordinated laptop stickers establish immediate team identification in co-working spaces, client offices, and public venues, facilitating networking and collaboration opportunities. This visual consistency becomes increasingly important as remote work and flexible office arrangements blur traditional workplace boundaries.

Team identity development through laptop customization extends beyond simple logo placement to encompass department colors, project identifications, and achievement recognition. Creative applications might include role-specific designs, tenure recognition badges, or project milestone acknowledgments that celebrate individual contributions while maintaining overall brand consistency. These approaches enhance employee engagement while providing external brand reinforcement.

Promotional giveaway strategies leverage laptop stickers’ broad appeal and practical utility to create meaningful customer touchpoints that generate lasting brand impressions. Unlike traditional promotional items with limited utility or appeal, laptop stickers offer universal relevance across demographic and professional boundaries, making them valuable additions to trade show distributions, client appreciation programs, and loyalty initiatives.

Educational institutions particularly benefit from laptop sticker programs that combine school pride with practical utility. University bookstores, student organizations, and alumni associations find consistent demand for quality stickers featuring school logos, mascots, and program identifications. These applications create ongoing brand visibility while generating revenue streams and community engagement.

Cost-effective marketing analysis reveals laptop stickers’ exceptional value proposition compared to traditional advertising channels. Promotional products typically achieve lower cost-per-impression rates than digital advertising while providing significantly longer exposure duration. A quality laptop sticker may generate daily impressions for 2-3 years, creating cumulative exposure value far exceeding initial investment costs.

Return on investment calculations should consider both direct and indirect benefits, including brand awareness generation, customer acquisition facilitation, employee engagement enhancement, and professional image reinforcement. Studies indicate that 83% of people experience strengthened brand relationships after receiving promotional products, with laptop stickers offering particularly strong emotional connections due to daily interaction and personal device attachment.

Design considerations for business applications require balancing brand compliance with aesthetic appeal and professional appropriateness. Corporate brand guidelines typically specify color palettes, typography standards, and logo usage requirements that must be maintained across all branded materials, including laptop stickers. Professional design consultation ensures compliance while optimizing visual impact within guideline constraints.

Scalability considerations become important for organizations requiring consistent branding across multiple sticker sizes or applications. Vector-based logos and simple, bold designs maintain clarity and impact across size variations, while complex graphics may become illegible or cluttered when reduced to laptop sticker dimensions. Testing designs at actual size before full production prevents disappointing results and ensures effective communication.

Contact information integration requires careful consideration of privacy, relevance, and updating requirements. While including phone numbers or email addresses may seem beneficial, this information becomes outdated quickly and creates maintenance challenges. Website URLs or social media handles often provide better long-term value while directing interested parties to current information sources.

Bulk ordering benefits extend beyond unit cost savings to encompass production consistency, quality control, and coordinated distribution capabilities. Volume orders typically qualify for enhanced design services, production scheduling priority, and quality guarantees that ensure consistent results across large quantities. These benefits become particularly important for organizations requiring exact color matching and consistent quality across multiple order batches.

Supply chain management for ongoing laptop sticker needs benefits from establishing relationships with reliable suppliers who understand organizational requirements and quality standards. Regular suppliers often provide design storage services, reorder simplification, and production scheduling flexibility that streamlines procurement processes while ensuring consistent results.

Australian business advantages include supporting local suppliers who understand climate requirements, provide faster turnaround times, and offer personalized service relationships. Local production capabilities enable rapid response to urgent requirements while supporting Australian economic development and reducing environmental impact through shortened supply chains.

Cultural relevance becomes important for businesses operating within Australian markets, where local imagery, references, and aesthetic preferences resonate more effectively than generic international approaches. Suppliers familiar with Australian business culture and consumer preferences provide valuable guidance for maximizing marketing effectiveness while avoiding cultural missteps.

Performance measurement strategies enable quantitative assessment of laptop sticker marketing effectiveness through various direct and indirect metrics. Brand awareness surveys, customer acquisition source tracking, and employee engagement measurements provide data supporting continued investment and program optimization. Digital integration through QR codes or custom URLs enables direct response tracking for more precise ROI calculation.

Social media monitoring for brand mentions, hashtag usage, and image sharing provides insights into organic brand amplification generated through laptop sticker visibility. Employees and stakeholders naturally share workspace images that include branded laptops, creating additional exposure through personal networks without additional marketing investment.

Regulatory and compliance considerations vary by industry and jurisdiction, with some professional environments restricting advertising materials or requiring specific approval processes. Legal, healthcare, and government sectors may have particular requirements that affect sticker design, placement, or usage policies. Understanding these constraints ensures program compliance while maximizing permitted opportunities.

Intellectual property protection becomes important when developing custom designs or incorporating licensed materials. Ensuring proper rights clearance for logos, fonts, and imagery prevents legal complications while protecting organizational reputation. Working with qualified design professionals helps navigate these requirements while developing effective creative solutions.

Understanding business applications and strategic considerations naturally leads into supplier selection criteria that ensure quality results and successful program implementation across diverse organizational requirements and performance expectations.

Selecting the right sticker provider determines both immediate satisfaction and long-term performance outcomes, making supplier evaluation a critical investment decision that impacts design quality, production reliability, and ongoing service relationships. Understanding key evaluation criteria, service differentiators, and local market advantages enables informed decisions that optimize both cost and quality outcomes.

Quality indicators provide objective measures for comparing suppliers and predicting performance outcomes across diverse applications and environmental conditions. Material specifications represent the foundation of quality assessment, with superior suppliers providing detailed technical data including adhesive strength ratings, UV resistance certifications, temperature tolerance ranges, and expected lifespan estimates. This transparency demonstrates professional expertise while enabling informed material selection for specific requirements.

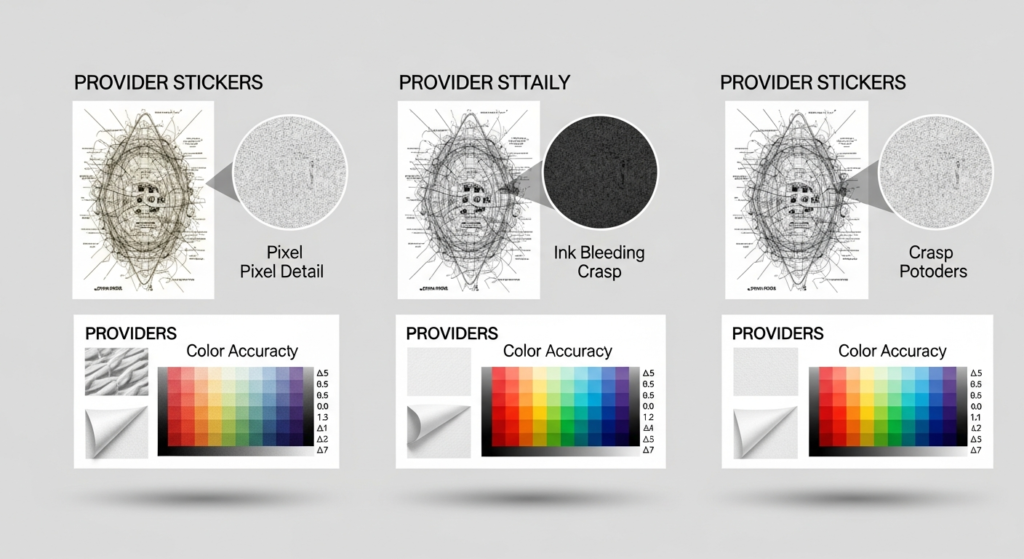

Printing technology capabilities significantly influence both visual quality and durability outcomes. Digital printing systems using eco-solvent or latex inks typically provide superior color accuracy, fade resistance, and environmental safety compared to older technologies. Advanced suppliers invest in color management systems that ensure consistent reproduction across different orders and materials, maintaining brand consistency for business applications.

Color accuracy verification through standardized testing processes distinguishes professional suppliers from hobbyist operations. Pantone color matching capabilities, ICC profile management, and proofing services ensure final products meet specific color requirements rather than approximations. This precision becomes particularly important for brand-critical applications where color consistency affects brand recognition and professional image.

Production capacity and equipment redundancy indicate supplier reliability and ability to meet deadlines consistently. Professional operations maintain multiple production lines and backup equipment to prevent service disruptions, while implementing quality control procedures that catch defects before shipping. Tour opportunities or facility descriptions provide insights into operational capabilities and quality commitment levels.

Service factors encompass the human elements that determine overall customer experience and project success beyond basic production capabilities. Design support services distinguish full-service providers from production-only suppliers, offering valuable expertise that optimizes design effectiveness while ensuring technical compatibility. Experienced design teams understand material limitations, application requirements, and aesthetic principles that amateur designers often overlook.

Customer service responsiveness provides crucial support throughout the project lifecycle, from initial consultation through post-delivery follow-up. Professional suppliers maintain clear communication channels, respond promptly to inquiries, and proactively address potential issues before they become problems. This support becomes particularly valuable for first-time sticker buyers who need guidance navigating material options, design requirements, and application procedures.

Revision policies and design iteration processes enable collaborative development that ensures final satisfaction without excessive costs or delays. Understanding revision limits, change procedures, and approval processes prevents misunderstandings while facilitating effective collaboration. Some suppliers offer unlimited revisions during initial design phases, while others charge for changes beyond specified limits.

Turnaround time capabilities balance production efficiency with quality requirements, enabling planning for both routine and urgent requirements. Standard production schedules provide baseline expectations, while rush service availability addresses urgent needs that arise in business environments. Understanding both capabilities and associated costs enables effective project planning and budget allocation.

Production scheduling transparency helps customers plan campaigns and coordinate with other marketing activities. Professional suppliers provide realistic timeframes and progress updates that enable effective project management, while unreliable providers often promise unrealistic delivery dates that create downstream problems and missed opportunities.

Australian market advantages extend beyond geographical convenience to encompass cultural understanding, regulatory compliance, and environmental considerations that benefit local buyers. Local suppliers understand Australian climate requirements and can recommend materials proven effective in local conditions, rather than generic recommendations that may prove inadequate for harsh Australian environments.

Reduced shipping times and costs provide both economic and environmental benefits while enabling faster response to urgent requirements. Local suppliers typically offer next-day delivery within major metropolitan areas, compared to 1-2 week international shipping that limits responsiveness and increases total project costs. This proximity also facilitates problem resolution through direct communication and local support.

Cultural familiarity with Australian business practices, aesthetic preferences, and regulatory requirements enables more effective collaboration and results. Local suppliers understand trademark requirements, business registration standards, and industry-specific regulations that affect commercial applications, providing guidance that prevents compliance issues.

Supporting local businesses contributes to Australian economic development while building relationships that provide ongoing value through personalized service, local references, and community connections. Many organizations prioritize local suppliers as part of corporate social responsibility initiatives, creating additional value beyond direct service benefits.

Pricing transparency enables accurate budget planning while preventing unexpected costs that compromise project viability. Professional suppliers provide detailed pricing structures that clearly separate design fees, setup costs, material charges, and shipping expenses. This transparency enables accurate cost comparison between suppliers while preventing budget surprises.

Hidden cost identification becomes crucial for accurate supplier comparison, as some providers advertise low base prices while recovering margins through setup fees, design charges, or premium shipping costs. Requesting total project costs including all fees and services provides accurate comparison basis and prevents budget overruns.

Bulk pricing structures and volume discounts benefit organizations with ongoing requirements or large initial orders. Understanding discount thresholds and volume requirements enables strategic order planning that maximizes cost efficiency while ensuring adequate supply. Some suppliers offer tiered pricing that provides increasing discounts based on order quantity or annual volume commitments.

Portfolio evaluation provides insights into supplier capabilities, experience levels, and quality standards through examples of completed projects. Diverse portfolio examples demonstrate versatility and experience across different industries, applications, and design styles. Requesting samples relevant to your specific requirements enables direct quality assessment before committing to larger orders.

Client testimonials and references provide third-party validation of service quality and reliability. Professional suppliers readily provide customer references and encourage direct communication with previous clients who can provide unbiased feedback about service experiences, quality outcomes, and problem resolution effectiveness.

Industry certifications and quality standards demonstrate commitment to professional practices and continuous improvement. Suppliers maintaining ISO certifications, industry association memberships, or environmental compliance certifications typically provide superior service quality and reliability compared to uncertified alternatives.

Technical capabilities encompass specialized services and advanced features that differentiate suppliers while enabling unique applications and enhanced performance. Custom cutting capabilities beyond standard die-cutting include laser cutting, kiss-cutting, and specialty shapes that enable unique designs impossible through traditional methods. Advanced cutting technologies provide precision and flexibility that support creative applications and brand differentiation.

Specialty material availability expands application possibilities beyond standard vinyl options. Suppliers offering metallic materials, textured finishes, holographic effects, or eco-friendly alternatives provide options for unique applications and specialized requirements. Understanding material catalogs and availability helps identify suppliers capable of supporting specific design visions.

Large format capabilities enable applications beyond individual laptop stickers to encompass full laptop skins, multiple-sticker sets, and coordinated branding programs. Suppliers with diverse size capabilities provide flexibility for expanding programs without requiring multiple vendor relationships.

Quality assurance processes demonstrate commitment to consistent results and customer satisfaction through systematic quality control and testing procedures. Professional suppliers implement inspection protocols, color verification systems, and packaging procedures that ensure products meet specifications before shipping. These processes prevent defective products while ensuring consistent quality across multiple orders.

Satisfaction guarantees and quality warranties provide protection against defective products while demonstrating supplier confidence in their capabilities. Understanding guarantee terms, claim procedures, and resolution processes ensures protection while providing insight into supplier reliability and customer service commitment.

Environmental and sustainability considerations increasingly influence supplier selection as organizations prioritize environmental responsibility alongside performance requirements. Suppliers offering eco-friendly materials, sustainable production processes, and recycling programs provide options that align with corporate sustainability goals while maintaining performance standards.

Local production reduces transportation environmental impact while supporting sustainable business practices. Understanding supplier environmental policies and certifications helps identify partners that align with organizational values while providing superior products and services.

Armed with comprehensive supplier evaluation criteria and local market insights, customers can confidently select partners capable of delivering superior results that meet both immediate requirements and long-term performance expectations, setting the foundation for successful laptop sticker programs that achieve aesthetic, functional, and business objectives.

Laptop stickers represent far more than simple decoration—they embody powerful tools for self-expression, brand communication, and professional identity that travel with you throughout your digital journey. Throughout this comprehensive exploration of Australia’s laptop customization landscape, we’ve uncovered the intricate details that separate exceptional results from mediocre attempts, providing the knowledge foundation necessary for making informed decisions that deliver lasting satisfaction.

The Australian laptop sticker market reflects our nation’s unique cultural identity while embracing global design trends and technological innovations. From the surf culture aesthetics of Queensland’s Gold Coast to Melbourne’s minimalist professional preferences, local customization choices reveal the diverse perspectives that define modern Australian digital culture. The substantial market growth—with personalized stickers valued at USD 4.84 billion globally in 2025—demonstrates the universal appeal of customization across demographic and professional boundaries.

Material selection emerges as the critical foundation determining both immediate visual impact and long-term performance success. Understanding the superior durability characteristics of premium vinyl materials, the subtle sophistication of clear applications, and the precision capabilities of die-cut options empowers informed decisions that align with specific requirements and environmental conditions. Australia’s challenging climate demands materials proven capable of withstanding intense UV exposure, temperature fluctuations, and humidity variations that would compromise inferior alternatives.

The design process represents where creativity meets technical reality, requiring careful balance between artistic vision and practical constraints. Current trends toward geometric patterns, holographic effects, and retro aesthetics provide inspiration while technical considerations—including resolution requirements, color mode selection, and copyright compliance—ensure professional execution. Whether pursuing personal expression or corporate branding objectives, effective design considers both immediate visual impact and scalable reproduction across various applications.

Professional application techniques distinguish amateur installations from results worthy of the investment in quality materials and custom designs. Surface preparation, systematic application methodology, and bubble prevention strategies ensure outcomes that maintain their professional appearance throughout their service life. The relatively small time investment in proper application techniques yields dramatically superior results compared to rushed attempts that compromise both aesthetics and longevity.

Maintenance practices extend sticker lifespan while preserving the visual impact that justifies the initial investment. Daily care requirements, appropriate cleaning methods, and environmental protection strategies prove surprisingly simple to implement while delivering significant performance benefits. Understanding wear indicators and replacement timing ensures consistently professional appearance that supports both personal satisfaction and business objectives.

Business applications reveal laptop stickers’ exceptional value proposition as mobile marketing tools that generate consistent brand exposure across diverse environments and audiences. The remarkable statistic that promotional products generate 500% more customer referrals than traditional advertising, combined with laptop stickers’ extended visibility duration, creates compelling return on investment arguments for organizations seeking cost-effective brand reinforcement strategies. Employee branding initiatives, promotional giveaway programs, and conference visibility strategies demonstrate versatile applications that extend far beyond simple decoration.

Supplier selection criteria provide the framework for identifying partners capable of delivering superior results through quality materials, professional services, and reliable delivery performance. Australian suppliers offer distinct advantages including climate expertise, cultural understanding, and logistics efficiency that benefit local customers while supporting domestic economic development. The investment in quality suppliers pays dividends through consistent results, responsive service, and ongoing support that facilitates program success.

The convergence of affordability, versatility, and performance makes laptop stickers accessible across all demographic and economic segments while delivering professional-quality results previously available only through expensive customization alternatives. This democratization of personalization enables individual expression and business branding without the significant investment required for cases, skins, or device replacement strategies.

Looking forward, laptop customization trends point toward increasing sophistication in both design aesthetics and material performance. Emerging technologies including smart materials, interactive elements, and sustainable alternatives promise expanded possibilities while maintaining the fundamental appeal of affordable, removable customization that adapts to changing preferences and requirements.

The environmental considerations driving material development align with growing sustainability awareness while maintaining performance standards essential for Australian conditions. Local suppliers increasingly emphasize eco-friendly materials and production processes that reduce environmental impact without compromising quality or durability expectations.

Ready to transform your laptop with custom stickers that perfectly capture your style or strengthen your brand presence? FastStickers.com.au combines over 15 years of Australian printing expertise with lightning-fast turnaround times and premium materials specifically selected for our challenging climate conditions.

Our comprehensive service offerings eliminate the guesswork from laptop customization:

Free design consultation with our experienced graphic design team ensures your vision translates into technically superior, visually stunning results. Our designers understand both creative possibilities and practical limitations, guiding you toward solutions that maximize impact while ensuring optimal performance.

2-3 day production with free express shipping Australia-wide gets your custom stickers delivered quickly without compromising quality. Our streamlined processes and local production capabilities enable rapid response to both routine and urgent requirements.

100% satisfaction guarantee on all custom laptop stickers provides complete confidence in your investment. We stand behind our materials, production quality, and service commitments with guarantees that reflect our confidence in superior outcomes.

Australian-made quality supports local businesses and jobs while ensuring materials proven effective in local conditions. Our local expertise and climate understanding deliver results that maintain their appearance and performance despite Australia’s environmental challenges.

Transform your laptop into a reflection of your personality or a powerful branding tool that generates consistent professional impressions. Join thousands of satisfied Australian customers who trust FastStickers.com.au for laptop customization that combines creative excellence with lasting performance.

Order your custom laptop stickers now or request a free quote to discover why FastStickers.com.au represents Australia’s premier choice for laptop sticker customization.

Transform your laptop. Express your identity. Make an impact.

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

The Complete Guide to Candle Labels: Design, Materials & Australian Compliance Australia’s candle market is experiencing unprecedented growth, with handcrafted and artisanal candles driving a $200+

The Aussie Choice for a Greener Tomorrow Eco-friendly stickers are no longer a niche choice—they’re quickly becoming the go-to for Aussie businesses and event organisers

Choosing the Perfect Sticker Type for Your Project: A Quick Guide Picking the right sticker can make or break your project. Many get stuck choosing

Harnessing Gippsland’s Printing Expertise for Australian Business Success Most Australian businesses settle for slow, generic printing from big companies. You don’t have to. Gippsland printing