Guide to Candle Labels

The Complete Guide to Candle Labels: Design, Materials & Australian Compliance Australia’s candle market is experiencing unprecedented growth, with handcrafted and artisanal candles driving a $200+

In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact with customers. What started as a pandemic-driven necessity has evolved into a permanent fixture of modern commerce, with 92% of Australian restaurants now offering QR code table ordering systems. This isn’t just a local trend—the global QR code market has surged to $10.5 billion and continues growing at an impressive 16.67% annually.

Behind these statistics lies a fundamental shift in customer expectations. Today’s Australian consumers demand instant access to information, seamless payment options, and contactless interactions that respect their time and health preferences. QR code stickers have emerged as the perfect bridge between digital convenience and physical presence, enabling businesses across Australia to meet these modern demands while simultaneously streamlining their operations.

Yet not all QR code implementations are created equal. The harsh Australian climate, diverse business environments, and specific regulatory requirements demand solutions that go far beyond basic printing. This is where quality, durability, and local expertise become critical differentiators.

Fast Stickers has positioned itself as Australia’s premier provider of high-quality, weather-resistant QR code stickers, specifically engineered for the unique challenges of the Australian market. From the tropical humidity of Queensland to the desert heat of the Northern Territory, Australian businesses need QR solutions that maintain their scanning reliability regardless of environmental conditions.

The transformation of Australian customer service through QR code implementation represents one of the most successful technology adoptions in recent business history. What began as an emergency response to social distancing requirements has evolved into a sophisticated ecosystem of customer engagement tools that deliver measurable business outcomes.

Contactless Menus and Ordering: The New Standard

The hospitality sector leads this revolution, with 70% of Australian restaurants now offering QR payment options that have fundamentally changed dining experiences. Restaurants implementing QR code menus report average reductions in wait times of 15-20 minutes per table, directly translating to improved table turnover rates and increased revenue potential. Beyond speed, these systems eliminate the hygiene concerns associated with shared physical menus while providing customers with detailed nutritional information, allergen warnings, and real-time availability updates.

Melbourne’s café culture exemplifies this transformation. Independent coffee shops that once struggled with peak-hour congestion now process orders seamlessly through QR code systems integrated with their point-of-sale infrastructure. Customers can arrive, scan a table sticker, place orders, and pay—all before a staff member even approaches their table. This efficiency allows businesses to maintain personal service where it matters most: food preparation and customer care.

Marketing Campaign Integration That Builds Relationships

Modern QR codes serve as powerful marketing bridges, connecting physical touchpoints to digital engagement strategies. Australian retailers are embedding QR codes into everything from storefront windows to product packaging, creating instant pathways to loyalty programs, social media communities, and exclusive offers. A furniture store in Sydney, for example, places QR codes on display items that link directly to customer reviews, styling inspiration, and financing options—transforming browsing into educated purchasing decisions.

The sophistication of these campaigns continues expanding. QR codes now trigger personalized experiences based on scan location, time of day, and customer history. A boutique clothing store might display different promotional content for morning commuters versus weekend shoppers, all through the same physical QR code sticker that intelligently adapts its digital destination.

Streamlined Event Management and Networking

Australia’s vibrant events industry has embraced QR codes as essential infrastructure for modern gatherings. Conference organizers report that QR-enabled check-ins reduce registration queues by up to 80%, while digital program distribution via QR codes eliminates printing costs and enables real-time updates. Attendees appreciate instant access to speaker biographies, session materials, and networking opportunities through a simple scan.

Wedding venues across Australia have discovered that QR codes transform guest experiences. Couples now place QR stickers on tables that link to photo-sharing platforms, menu explanations, and even interactive seating charts. This technology enables personalized touches that were previously impossible at large-scale events.

Instant Product Information Access

Research indicates that 51.5% of QR code usage focuses on product information delivery, reflecting consumers’ desire for immediate access to detailed specifications, reviews, and comparison data. Australian retailers leveraging this trend report increased customer confidence and reduced returns, as buyers make more informed decisions before purchasing.

Hardware stores exemplify this application brilliantly. Complex power tools that once required lengthy sales consultations now feature QR codes linking to video demonstrations, safety instructions, and compatibility guides. Customers can research thoroughly at their own pace, while staff focus on addressing specific questions and closing sales.

Payment Processing Revolution

The integration of QR codes with digital wallets and payment platforms has created the fastest, most secure payment experiences in Australian commerce history. Businesses report transaction completion times averaging 30% faster than traditional card payments, with dramatically reduced queue formations during peak periods.

Small businesses particularly benefit from QR payment systems that eliminate the need for expensive point-of-sale hardware while providing detailed transaction tracking and customer data insights. A food truck operator can now process payments as quickly as a major restaurant, leveling the playing field for independent operators.

These customer-facing applications represent just one dimension of QR code utility, as Australian businesses are simultaneously discovering powerful backend applications that transform operational efficiency from the ground up.

Beyond their customer-facing applications, QR code stickers are revolutionizing how Australian businesses manage their internal operations. From multinational corporations to family-owned shops, organizations are discovering that QR technology offers surprisingly sophisticated solutions for inventory management, asset tracking, and compliance monitoring—all at a fraction of the cost of traditional systems.

Real-Time Inventory Tracking That Actually Works

Traditional inventory management often relies on cumbersome spreadsheets, manual counting, and periodic audits that provide outdated information. QR codes for inventory management transform this process into real-time tracking systems that any staff member can operate with a smartphone or tablet.

Australian warehouses implementing QR inventory systems report accuracy improvements of 40-60% compared to manual processes. Each product, shelf location, and storage area receives a unique QR code sticker that links to cloud-based inventory databases. When items move, arrive, or ship, staff simply scan the relevant codes to update quantities automatically. This system eliminates the discrepancies that plague traditional stock management while providing managers with live visibility into inventory levels across multiple locations.

The impact extends beyond accuracy to operational speed. What once required hours of manual counting now completes in minutes. A Perth-based automotive parts distributor reduced their weekly inventory process from two full days to four hours, freeing staff for customer service and sales activities that directly impact revenue.

Intelligent Asset Management for Growing Businesses

Equipment tracking represents another powerful application where QR codes deliver enterprise-level functionality at small business prices. Pinnacle Software’s QR asset management solutions demonstrate how Australian companies are using QR stickers to monitor everything from office furniture to heavy machinery.

Construction companies face particular challenges in asset management, with tools and equipment moving constantly between job sites. QR code stickers attached to each asset create digital trails that track location, usage history, maintenance schedules, and operator assignments. When a piece of equipment requires service or inspection, managers can instantly access its complete history through a simple smartphone scan.

The financial benefits are substantial. Companies report 25-30% reductions in equipment loss and theft, while preventive maintenance scheduling increases asset lifespan by an average of 20%. For businesses with significant equipment investments, these improvements quickly offset the minimal cost of QR code implementation.

Eliminating Data Entry Errors and Improving Accuracy

Manual data entry remains one of the largest sources of costly errors in Australian businesses. QR codes virtually eliminate transcription mistakes by automating information capture and transfer. Instead of manually typing product codes, serial numbers, or location identifiers, staff scan QR codes that instantly populate databases with accurate information.

A Brisbane-based medical supply company discovered that QR code implementation reduced data entry errors by 95%, while simultaneously improving processing speed by 40%. Critical healthcare supplies now move through their facility with unprecedented accuracy, supporting the reliability that medical professionals demand.

Seamless Integration with Popular Business Software

Modern QR code systems integrate effortlessly with cloud-based inventory management platforms already popular among Australian businesses. INVENTAR’s mobile inventory tracking exemplifies how QR technology enhances existing business software without requiring complete system overhauls.

These integrations mean businesses can implement QR tracking gradually, starting with high-value items or frequently moved inventory. As staff become comfortable with the technology, coverage can expand until entire operations benefit from QR-enabled tracking and management.

Cost-Effective Alternative to Complex RFID Systems

Radio Frequency Identification (RFID) systems offer sophisticated tracking capabilities but require substantial investments in specialized hardware and infrastructure. QR codes deliver many of the same benefits using smartphones and tablets that businesses already own, making advanced tracking accessible to organizations of all sizes.

Small to medium enterprises particularly benefit from QR solutions that provide professional-grade tracking without enterprise-level costs. A family-owned manufacturing business can implement QR asset tracking for hundreds of dollars rather than the thousands required for RFID infrastructure.

Compliance and Quality Control Applications

Australian businesses operating in regulated industries find QR codes invaluable for maintaining compliance documentation and audit trails. Food manufacturers use QR codes to track ingredients from supplier to finished product, ensuring complete traceability in case of quality issues or recalls.

Quality control processes become more reliable when inspectors can scan QR codes to access checklists, record findings, and timestamp activities automatically. This documentation proves invaluable during regulatory audits while ensuring consistent quality standards across all locations and shifts.

While these operational applications demonstrate QR codes’ versatility and value, successful implementation depends critically on proper design principles that ensure reliable scanning across all Australian business environments and conditions.

The difference between a QR code that works occasionally and one that performs flawlessly every time lies in understanding the technical principles that govern scanning reliability. Australian businesses operating across diverse environments—from air-conditioned offices to outdoor markets, from pristine retail spaces to dusty workshops—require QR codes engineered for consistent performance regardless of conditions.

Size Specifications That Guarantee Scanning Success

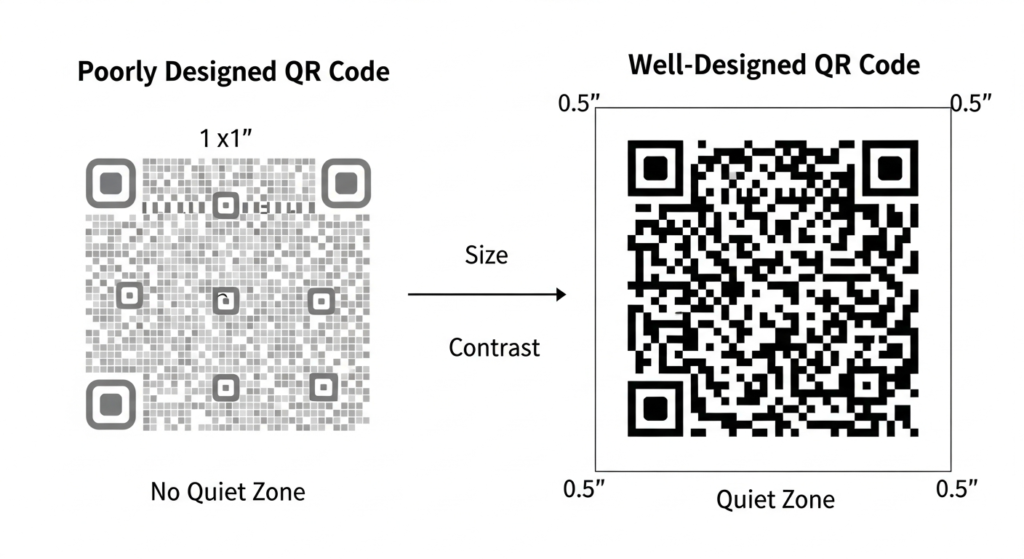

Size represents the most critical factor in QR code reliability, yet many businesses underestimate its importance. While regulatory compliance requires a minimum of 1cm x 1cm, Nielsen Norman Group’s QR Code Usability Guidelines recommend specific dimensions based on scanning distance and application environment.

For table-top applications in restaurants and cafés, 1×1 inch (2.5cm x 2.5cm) provides optimal scanning reliability for customers using smartphones at comfortable distances. This size accommodates variations in phone camera quality, hand steadiness, and ambient lighting conditions that occur in real-world dining environments.

Wall and window applications require larger dimensions—typically 2×2 inches (5cm x 5cm)—to account for increased scanning distances. Customers approaching from several feet away need QR codes large enough for their phone cameras to detect and focus on quickly. Undersized codes force customers to move uncomfortably close to surfaces, creating awkward interactions that reduce scanning success rates.

Outdoor applications demand even larger sizes to overcome environmental challenges like bright sunlight, shadows, and weather-related visibility issues. Marketing displays and signage typically require 3×3 inch (7.5cm x 7.5cm) or larger QR codes to ensure reliable scanning from typical viewing distances.

Contrast Requirements for Universal Readability

High contrast between QR code elements and background colors determines scanning reliability more than any other design factor. QR Code Kit’s comprehensive legibility guide emphasizes that insufficient contrast represents the primary cause of scanning failures across all environments.

Black codes on white backgrounds provide optimal contrast for most applications, but Australian businesses often want to incorporate brand colors into their QR designs. Dark navy, forest green, or burgundy can work effectively on white or light backgrounds, but testing across multiple devices and lighting conditions becomes essential.

The contrast challenge intensifies in outdoor environments where bright Australian sunlight can wash out subtle color differences. QR codes displayed in windows, on outdoor signs, or vehicle graphics require maximum contrast to maintain scanning reliability during peak daylight hours.

Quiet Zone Protection Against Interference

The quiet zone—the clear border space surrounding QR codes—prevents visual interference that can disrupt scanning algorithms. QR Code Generator’s design best practices specify minimum quiet zone requirements, but Australian applications often benefit from larger margins.

Busy visual environments like retail displays, trade show booths, and marketing materials require expanded quiet zones to separate QR codes from surrounding graphics, text, and images. A QR code surrounded by colorful promotional content needs more breathing room than one placed on a clean, minimal background.

Restaurant table applications present unique quiet zone challenges, as QR codes must coexist with table numbers, promotional materials, and dining accessories. Strategic placement and adequate spacing ensure QR codes remain scannable despite visual competition from other table elements.

Error Correction Levels for Environmental Resilience

QR codes include built-in error correction that enables successful scanning even when portions of the code become damaged or obscured. Four levels—L (Low), M (Medium), Q (Quartile), and H (High)—provide different degrees of redundancy appropriate for various Australian business applications.

Indoor applications with minimal wear typically function well with Level M error correction, which allows for 15% data recovery. This level provides good scanning reliability while maximizing data capacity for longer URLs or detailed information.

Outdoor applications, high-traffic areas, and environments with potential for physical damage benefit from Level Q or Level H error correction. These higher levels sacrifice some data capacity but ensure scanning reliability even when stickers experience scratching, fading, or partial obstruction.

Level H error correction proves particularly valuable for permanent installations like building directories, equipment labels, or long-term marketing displays where replacement costs make reliability paramount.

File Quality Standards for Professional Reproduction

Vector file formats ensure QR codes maintain crisp edges and precise contrast ratios when reproduced at any size. Raster images (JPG, PNG) can introduce compression artifacts that compromise scanning reliability, particularly when codes are enlarged or reduced from their original dimensions.

Professional printing requires QR codes supplied as vector files (AI, EPS, PDF) with embedded fonts and proper color specifications. This ensures reproduction quality remains consistent across different printing equipment and materials.

Resolution becomes critical when working with raster formats. QR codes require minimum 300 DPI resolution at final print size to maintain scanning reliability, with 600 DPI preferred for critical applications where scanning failure could impact business operations.

Comprehensive Testing Protocols Before Production

Successful QR code implementation requires systematic testing across the devices and conditions that customers will encounter. Testing protocols should include various smartphone models, different lighting conditions, and multiple scanning distances to identify potential issues before production.

Android and iPhone cameras use different scanning algorithms and autofocus systems, making cross-platform testing essential. QR codes that scan perfectly on new iPhones might struggle with older Android devices, particularly in challenging lighting conditions.

Environmental testing simulates real-world conditions where QR codes will be used. Outdoor codes should be tested in direct sunlight, shade, and twilight conditions. Indoor codes require testing under various lighting types—fluorescent, LED, and natural light—to ensure consistent performance.

Once design excellence is achieved, selecting materials that maintain these performance standards under Australian environmental conditions becomes the next critical success factor.

Australia’s diverse and often harsh environmental conditions demand QR code materials engineered for exceptional durability and longevity. From the tropical humidity of Darwin to the desert heat of Alice Springs, from the coastal salt air of Perth to the alpine freeze-thaw cycles of the Snowy Mountains, Australian businesses need QR code stickers that maintain their scanning reliability regardless of environmental extremes.

Vinyl Excellence: The Foundation of Outdoor Durability

Premium vinyl represents the gold standard for Australian QR code applications, offering a unique combination of durability, printability, and cost-effectiveness that makes it ideal for both indoor and outdoor use. Inovar Packaging’s weatherproof QR code label guide demonstrates why vinyl has become the material of choice for demanding Australian applications.

High-quality vinyl stickers feature UV-stable pigments that resist the intense Australian sun. Unlike paper-based materials that fade within months of outdoor exposure, premium vinyl maintains its contrast and scanning reliability for 4+ years even under constant UV bombardment. This longevity makes vinyl cost-effective for permanent installations like building directories, equipment labels, and outdoor marketing displays.

The flexibility of vinyl accommodates surface expansion and contraction caused by temperature fluctuations without cracking or peeling. This characteristic proves crucial for applications on metal surfaces, vehicles, and outdoor equipment that experience significant temperature variations throughout Australian seasonal cycles.

Vinyl’s smooth surface texture provides optimal contrast for QR code printing while resisting dirt accumulation and moisture absorption. Unlike textured materials that can trap contaminants or create visual noise that interferes with scanning, vinyl maintains clean, precise code reproduction throughout its service life.

Advanced Adhesive Technology for Permanent Bonding

The adhesive system represents a critical but often overlooked component of QR code sticker performance. 2mil adhesive thickness provides the aggressive initial tack and long-term bond strength necessary for Australian environmental conditions. This specification ensures stickers adhere immediately upon application while developing stronger bonds over time.

Pressure-sensitive adhesives formulated for Australian conditions resist temperature-induced failure and maintain bonding strength across humidity extremes. Standard adhesives often fail during hot Australian summers when surface temperatures can exceed 70°C, but premium formulations continue performing reliably under these challenging conditions.

The adhesive chemistry must also resist UV degradation to prevent brittleness and bond failure over time. Quality adhesives maintain their flexibility and bonding properties for years, even under intense UV exposure that would quickly compromise inferior formulations.

Protective Lamination for Extended Service Life

Clear protective lamination adds a crucial durability layer that dramatically extends QR code service life in demanding applications. Custom Stickers’ field-tested durability guide demonstrates how lamination protects against scratching, chemical exposure, and wear that could compromise scanning reliability.

Lamination becomes particularly important for QR codes in high-traffic areas where physical contact is inevitable. Restaurant table stickers, retail displays, and equipment labels benefit significantly from lamination that prevents scratches from cleaning, handling, or accidental contact.

Chemical resistance provided by quality lamination protects QR codes from cleaning solvents, food spills, and environmental contaminants that could stain or damage unprotected prints. This protection proves essential in commercial kitchens, workshops, and outdoor applications where chemical exposure is unavoidable.

Anti-glare lamination options improve scanning reliability under bright lighting conditions by reducing reflection and hotspots that can interfere with camera autofocus systems. This treatment particularly benefits QR codes placed in windows or under fluorescent lighting where glare could impede scanning.

Indoor Versus Outdoor Material Specifications

Indoor QR code applications can utilize a broader range of materials while still maintaining excellent performance and cost-effectiveness. Paper-based materials with protective coatings provide sufficient durability for indoor environments while offering superior printability for fine details and small text elements.

However, indoor applications still benefit from vinyl materials when longevity and professional appearance are priorities. Vinyl stickers maintain their crisp appearance indefinitely in indoor environments, while paper materials may show wear or aging over time.

Outdoor applications demand vinyl construction as a minimum requirement, with additional considerations for extreme exposure conditions. Marine environments require enhanced UV and salt resistance, while industrial applications may need chemical-resistant formulations.

Climate-Specific Testing and Validation

Australian climate conditions require materials tested specifically for local environmental extremes rather than generic international standards. Temperature cycling between freezing nights and 40°C+ days creates expansion and contraction stresses that can cause inferior materials to fail prematurely.

Humidity resistance becomes critical in tropical regions where moisture levels can exceed 90% for extended periods. Materials must resist moisture absorption that could cause dimensional changes, adhesive failure, or print degradation.

UV exposure testing must reflect Australian solar intensity, which can be significantly higher than testing standards developed for northern hemisphere conditions. Materials that perform adequately in European or North American conditions may fail rapidly under intense Australian sunlight.

Surface Compatibility and Application Guidelines

Different surface materials require specific adhesive formulations and application techniques to ensure optimal bonding and longevity. Glass surfaces provide excellent adhesion for most quality adhesives, while textured metals may require specially formulated adhesives for reliable bonding.

Painted surfaces present unique challenges, as adhesive compatibility with paint chemistry determines long-term bond reliability. Some paints may soften or discolor when exposed to certain adhesive formulations, making material selection critical for painted metal or wood surfaces.

Plastic surfaces vary widely in their adhesive compatibility, with some formulations (particularly low-energy plastics like polyethylene) requiring special adhesive chemistry for reliable bonding. Professional material suppliers can provide guidance on optimal adhesive selection for specific plastic substrates.

Proper surface preparation ensures maximum adhesive performance regardless of substrate type. Clean, dry surfaces free from oils, dust, and chemical residues provide optimal conditions for adhesive bonding and long-term durability.

Beyond material quality and durability, Australian businesses must navigate specific regulatory requirements that govern QR code implementation across various industries and applications.

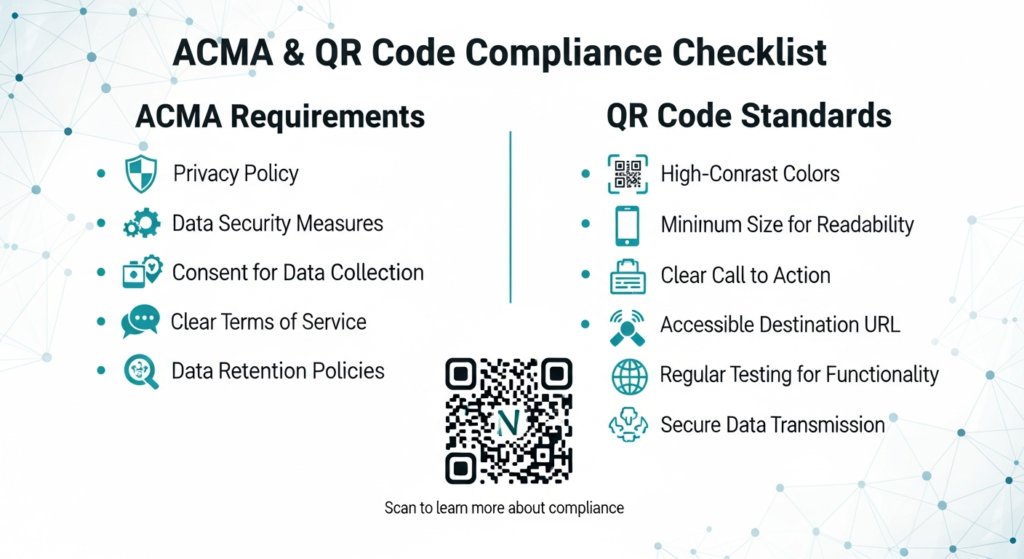

Australian businesses implementing QR code solutions must navigate a regulatory landscape that balances technological innovation with consumer protection, accessibility requirements, and industry-specific compliance standards. Understanding these requirements ensures QR code implementations enhance business operations while maintaining full regulatory compliance.

ACMA Telecommunications Labelling Revolution

The Australian Communications and Media Authority (ACMA) has revolutionized telecommunications equipment labelling by accepting QR codes as compliance labels with specific linking and sizing requirements. This regulatory advancement enables Australian electronics manufacturers and importers to streamline compliance while providing consumers with immediate access to comprehensive safety and technical information.

The ACMA framework requires QR codes linking to telecommunications compliance information to meet minimum 3mm height specifications, ensuring readability across all consumer devices. This requirement balances space efficiency for product labelling with practical usability for consumers seeking compliance information.

QR code compliance labelling must link directly to Australian-specific regulatory information rather than generic international content. This ensures consumers access relevant safety data, frequency allocations, and usage restrictions that apply specifically to Australian telecommunications networks and regulations.

The linked digital content must remain accessible and current throughout the product’s expected service life. Manufacturers cannot use temporary URLs or remove compliance information after initial product approval, creating ongoing obligations for digital content maintenance and accessibility.

ACMA’s consultation process on QR code telecommunications labelling demonstrates the authority’s commitment to modernizing compliance frameworks while maintaining consumer protection standards. This collaborative approach between industry and regulators creates practical solutions that benefit both businesses and consumers.

AusPayNet Guidelines for Financial Transactions

QR codes facilitating financial transactions must comply with AusPayNet guidelines that ensure security, accessibility, and consumer protection across all payment scenarios. These requirements apply to any QR code linking to payment platforms, digital wallets, or merchant payment systems.

Payment QR codes must provide clear disclosure of transaction amounts, merchant identification, and payment platform details before processing any charges. This transparency protects consumers from unclear or unauthorized charges while building confidence in QR-enabled payment systems.

Security requirements mandate encrypted connections and validated merchant credentials for all QR code payment links. Payment platforms must implement fraud monitoring and dispute resolution systems that meet Australian banking standards for consumer protection.

Accessibility standards require payment QR codes to include alternative access methods for consumers with visual impairments or older devices that may have scanning limitations. This might include phone numbers for voice-based transactions or text-based payment instructions.

Website Compliance for QR Code Destinations

QR codes linking to websites or digital platforms must ensure destination compliance with Australian digital accessibility and consumer protection laws. This creates ongoing obligations beyond the physical QR code implementation to include the entire digital user experience.

Privacy Act compliance becomes essential when QR codes collect consumer information or enable tracking across digital platforms. Businesses must provide clear privacy disclosures and obtain appropriate consent for data collection, particularly when QR codes enable marketing automation or customer profiling.

Website accessibility standards under the Disability Discrimination Act apply to all QR code destination content. Sites must provide text alternatives for images, keyboard navigation options, and screen reader compatibility to ensure universal access regardless of disability status.

Consumer protection laws require accurate and current information on all QR-linked content, with clear contact details and dispute resolution processes for any commercial transactions or service offerings accessed through QR codes.

Accessibility Considerations Under Australian Law

The Disability Discrimination Act creates specific obligations for QR code implementations to ensure equal access for all Australians regardless of disability status. These requirements go beyond basic compliance to create inclusive experiences that serve all customers effectively.

Visual accessibility requires QR codes to include tactile or audio alternatives for customers with visual impairments. This might include raised textures near QR codes that alert customers to their presence, or audio instructions that explain QR code functionality and alternative access methods.

Cognitive accessibility considerations ensure QR code interfaces remain simple and intuitive for users with learning disabilities or cognitive impairments. Clear instructions, simple language, and straightforward navigation paths help ensure universal usability.

Motor accessibility requirements acknowledge that some customers may have difficulty holding or positioning smartphones for QR scanning. Alternative access methods like phone numbers, voice commands, or staff assistance ensure services remain accessible to all customers.

Technology accessibility recognizes that not all customers own smartphones capable of QR scanning. Businesses must provide alternative access methods that ensure QR-enabled services remain available to customers using basic mobile phones or those who prefer traditional service delivery methods.

Industry-Specific Regulatory Requirements

Healthcare applications face additional regulatory requirements under therapeutic goods administration (TGA) guidelines and health information privacy laws. QR codes linking to health information must comply with secure communication standards and patient consent requirements.

Food service applications must consider food safety regulations when QR codes replace physical menus or enable food ordering. Digital menu information must remain accurate and current, with clear allergen warnings and nutritional information that meets Australian food labelling standards.

Retail applications involving QR codes for product information or pricing must comply with Australian Consumer Law requirements for accurate advertising and clear pricing disclosure. QR-linked product information becomes part of the commercial representation and must meet truth in advertising standards.

Educational institutions using QR codes must consider student privacy laws and age-appropriate content restrictions. QR codes in schools or universities must link to content that meets institutional safety and educational standards.

Practical Compliance Implementation Strategies

Successful QR code compliance begins with understanding the specific regulatory requirements that apply to each business application and industry context. Professional legal advice may be necessary for complex implementations or regulated industries.

Documentation systems should track QR code implementations, destination URLs, and compliance measures to demonstrate ongoing regulatory adherence during any regulatory reviews or audits.

Regular compliance audits ensure QR-linked content remains current and compliant as regulations evolve or business operations change. This proactive approach prevents compliance issues from developing over time.

Staff training ensures employees understand compliance obligations and can assist customers who may need alternative access methods or have questions about QR code functionality and data collection practices.

With design principles mastered, materials selected, and compliance requirements understood, successful QR code implementation requires strategic deployment planning and partnerships with experienced production specialists who understand Australian business needs.

Transforming QR code concepts into successful customer engagement requires strategic implementation that considers placement psychology, technical testing, staff preparedness, and ongoing performance optimization. The most brilliantly designed QR codes fail if customers cannot find them, scan them easily, or understand their purpose immediately upon interaction.

Strategic Placement Psychology for Maximum Engagement

QR code placement determines customer interaction rates more than any other single factor. Successful placement requires understanding customer behavior patterns, sight lines, and natural interaction flows within specific business environments.

In restaurant settings, table placement must balance visibility with dining experience aesthetics. QR codes positioned at the table edge closest to the entry point capture attention as customers settle into their seats, while avoiding interference with conversation or dining activities. Height positioning should accommodate both seated adults and standing customers, typically 6-8 inches from the table edge.

Retail environments benefit from QR code placement at decision points where customers naturally pause to evaluate products. Shelf-level placement near price displays creates logical scanning opportunities, while window displays should position QR codes at average eye height for pedestrians (approximately 1.5 meters from ground level).

Service businesses like automotive repair shops or professional offices achieve best results with QR codes placed at waiting areas where customers have time and motivation to engage with additional information. Reception desks, waiting room tables, and service counters provide natural scanning opportunities without disrupting business operations.

Comprehensive Pre-Deployment Testing Protocols

Systematic testing across real-world conditions identifies potential scanning issues before customer-facing deployment. Testing protocols should simulate actual customer usage scenarios rather than ideal laboratory conditions.

Device testing must include various smartphone models across different age ranges and operating systems. Current iPhones and Android devices may scan QR codes effortlessly, but older devices or budget smartphones might struggle with certain size or contrast combinations. Testing should include low-light conditions, bright sunlight, and typical indoor lighting to ensure universal scanning reliability.

Distance testing determines optimal QR code sizing for intended scanning distances. Customers should be able to scan successfully from comfortable distances without awkward positioning or multiple attempts. Testing from 1-3 feet helps optimize QR code sizing for typical handheld scanning scenarios.

Angle testing addresses real-world scanning conditions where customers approach QR codes from various directions. Codes should remain scannable from 30-degree angles to accommodate natural approach patterns and varying customer heights.

Network connectivity testing ensures QR code destinations load quickly and reliably on typical Australian mobile networks. Slow-loading destinations frustrate customers and reduce engagement rates, making optimization crucial for implementation success.

Staff Training and Customer Service Integration

Successful QR code implementations require staff training that enables confident customer assistance and troubleshooting. Employees should understand QR code functionality well enough to explain benefits and assist customers experiencing scanning difficulties.

Training should cover basic smartphone QR scanning procedures across different devices, enabling staff to provide hands-on assistance when needed. This capability proves particularly valuable for older customers or those unfamiliar with QR technology.

Staff should understand QR code destinations and functionality to answer customer questions and provide alternative access methods when scanning fails. This knowledge ensures QR implementation enhances rather than complicates customer service delivery.

Troubleshooting training helps staff identify and resolve common scanning issues like poor lighting, incorrect distance, or device compatibility problems. Quick problem resolution maintains positive customer experiences even when technical issues occur.

Performance Monitoring and Optimization Systems

QR code analytics provide valuable insights into customer engagement patterns, scanning success rates, and content performance that inform ongoing optimization efforts. Modern QR platforms offer detailed tracking that reveals usage patterns and identifies improvement opportunities.

Scan rate monitoring tracks how many customers attempt to scan QR codes versus total exposure opportunities. Low scan rates might indicate placement issues, size problems, or unclear value propositions that require adjustment.

Completion rate analysis measures how many successful scans result in desired customer actions like orders, information requests, or marketing engagement. Low completion rates suggest destination content optimization needs rather than QR code technical issues.

Time-based analytics reveal peak usage patterns that can inform staffing decisions and promotional timing. Understanding when customers engage most frequently with QR codes enables businesses to optimize resources and support systems.

Geographic analytics for businesses with multiple locations identify successful implementation patterns that can be replicated across other sites. This data-driven approach accelerates QR deployment success while avoiding repeated mistakes.

Fast Stickers’ Production Excellence for Australian Businesses

Implementation success depends heavily on production quality, delivery reliability, and ongoing support that enables businesses to deploy QR solutions without operational disruption. Fast Stickers’ vinyl sticker specifications demonstrate the production excellence that Australian businesses require for successful QR implementations.

The 2-3 day turnaround times enable businesses to implement QR solutions quickly in response to market opportunities or operational needs. This production speed proves crucial for seasonal businesses, promotional campaigns, or rapid expansion scenarios where delays could impact business outcomes.

Express nationwide shipping ensures QR code stickers reach Australian businesses regardless of location, enabling consistent implementation timelines across urban and regional markets. This reliability allows businesses to coordinate QR launches across multiple locations simultaneously.

Free design consultation services provide professional expertise that optimizes QR implementations before production begins. This consultation helps businesses avoid common design mistakes while ensuring optimal scanning performance for their specific applications and environments.

Quality control processes ensure every QR code meets scanning reliability standards before shipping, eliminating the risk of printing errors or quality issues that could compromise customer experiences. This quality assurance gives businesses confidence in their QR implementations.

Scaling Success Across Multiple Locations

Businesses with multiple locations benefit from standardized QR implementation procedures that ensure consistent customer experiences while accommodating local requirements. Centralized design and production combined with location-specific content creates optimal scalability.

Template systems enable rapid deployment of QR solutions across new locations while maintaining brand consistency and scanning reliability. These templates can be customized for local content while preserving proven design elements and technical specifications.

Training standardization ensures staff across all locations can provide consistent QR code support and customer assistance. This consistency builds customer confidence and reduces confusion when customers encounter QR codes at different business locations.

Performance benchmarking across locations identifies successful implementation patterns and reveals improvement opportunities. This comparative analysis accelerates optimization while ensuring all locations benefit from collective learning and experience.

The strategic implementation of QR code stickers represents far more than a simple technology upgrade—it embodies a fundamental transformation in how Australian businesses engage with customers while optimizing internal operations for sustainable growth and competitive advantage.

The transformation of Australian commerce through QR code technology represents more than a technological trend—it embodies a fundamental shift toward integrated digital-physical experiences that meet modern customer expectations while delivering unprecedented operational efficiency. From the bustling cafés of Melbourne to the remote mining operations of Western Australia, QR code stickers have proven their value across every industry and environment.

The statistics speak volumes about this revolution: 92% of Australian hospitality businesses have embraced QR code solutions, while the global market continues expanding at 16.67% annually. But behind these numbers lies a deeper story of businesses discovering that QR codes deliver immediate, measurable improvements in customer satisfaction, operational efficiency, and competitive positioning.

The Critical Success Factors

Successful QR implementations require more than basic understanding—they demand attention to design excellence, material quality, regulatory compliance, and strategic deployment. QR codes that work reliably under Australian conditions require careful attention to size specifications, contrast ratios, quiet zone protection, and error correction levels appropriate for their intended environments.

Material selection proves equally crucial, as Australian environmental conditions demand UV-resistant vinyl with premium adhesives and protective lamination. These specifications ensure QR codes maintain scanning reliability throughout their intended service life, regardless of exposure to intense sunlight, temperature extremes, or environmental challenges.

Regulatory compliance adds another layer of complexity, with ACMA telecommunications guidelines, AusPayNet payment standards, and accessibility requirements creating obligations that extend beyond the physical QR code to encompass the entire customer experience. Understanding these requirements ensures implementations enhance business operations while maintaining full legal compliance.

Beyond Technology: Strategic Business Advantage

The most successful Australian businesses view QR codes not as isolated technology solutions but as strategic tools that bridge physical and digital customer touchpoints. This perspective enables QR implementations that deliver compound benefits across customer experience, operational efficiency, marketing effectiveness, and competitive differentiation.

Customer experience improvements through contactless interactions, instant information access, and streamlined transactions create measurable increases in satisfaction and loyalty. These benefits translate directly into improved customer retention and positive word-of-mouth marketing that drives sustainable business growth.

Operational efficiency gains through automated inventory tracking, asset management, and compliance monitoring reduce costs while improving accuracy and reliability. These improvements free staff for higher-value activities while providing managers with real-time visibility into business operations.

Marketing integration through QR-enabled campaigns creates new opportunities for customer engagement, data collection, and personalized communications that strengthen brand relationships while driving sales growth.

The Australian Advantage

Australian businesses implementing QR solutions with local expertise and production capabilities enjoy significant advantages over competitors relying on generic international suppliers. Understanding Australian environmental conditions, regulatory requirements, and market preferences enables QR implementations that perform reliably while meeting local expectations.

Fast production turnaround times enable rapid deployment that captures market opportunities and responds quickly to changing business needs. This agility proves particularly valuable in Australia’s dynamic business environment where seasonal fluctuations and market opportunities require flexible operational responses.

Local support and consultation services ensure QR implementations succeed from initial planning through ongoing optimization. This partnership approach reduces implementation risks while maximizing the business value of QR technology investments.

The integration of QR technology into Australian business operations represents a permanent shift rather than a temporary trend. As digital natives become the dominant customer demographic and operational efficiency becomes increasingly critical for competitive success, QR codes will evolve from optional enhancements to essential business infrastructure.

Ready to Transform Your Business with Professional QR Code Stickers?

Partner with Fast Stickers, Australia’s premier custom sticker specialist, for QR code solutions that work reliably in Australian conditions. With 15+ years of printing expertise, 2-3 day production times, and free nationwide shipping, we make QR code implementation simple and successful.

Our team understands the unique challenges of Australian business environments, from tropical humidity to desert heat, from urban density to remote operations. We’ve helped thousands of Australian businesses implement QR solutions that enhance customer experiences while improving operational efficiency.

Get started today:

Contact Fast Stickers now and discover why Australian businesses trust us for lightning-fast, professional-quality stickers that deliver results.

The Complete Guide to Candle Labels: Design, Materials & Australian Compliance Australia’s candle market is experiencing unprecedented growth, with handcrafted and artisanal candles driving a $200+

The Aussie Choice for a Greener Tomorrow Eco-friendly stickers are no longer a niche choice—they’re quickly becoming the go-to for Aussie businesses and event organisers

Choosing the Perfect Sticker Type for Your Project: A Quick Guide Picking the right sticker can make or break your project. Many get stuck choosing

Harnessing Gippsland’s Printing Expertise for Australian Business Success Most Australian businesses settle for slow, generic printing from big companies. You don’t have to. Gippsland printing

Picture this: you’ve invested months developing the perfect food product, secured distribution partners, and launched with enthusiasm—only to face a devastating product recall because your