QR Code Stickers Australia

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

In today’s rapidly evolving business landscape, Australian companies face mounting pressure to balance environmental responsibility with operational efficiency. From Melbourne’s bustling startup scene to Perth’s mining industry, businesses across the continent are discovering that sustainable packaging choices aren’t just about environmental stewardship—they’re about future-proofing their operations and meeting evolving consumer expectations.

Among the seemingly small but significant packaging decisions that companies make daily, stickers and labels represent a unique opportunity to demonstrate environmental commitment without compromising functionality. Whether you’re a craft brewery in Tasmania needing waterproof bottle labels, a Sydney-based e-commerce company seeking branded packaging stickers, or a Queensland agricultural business requiring product identification labels, the move toward eco-friendly alternatives has never been more accessible or beneficial.

Yet misconceptions persist. Many business owners still believe that choosing eco-friendly stickers means accepting compromises in quality, durability, or production speed. Others worry that sustainable options will disrupt their established workflows or inflate their packaging budgets. These concerns, while understandable, often stem from outdated information about first-generation eco-friendly products that struggled to match conventional performance standards.

This comprehensive guide dismantles those misconceptions while providing you with the knowledge needed to make informed decisions about eco-friendly stickers. We’ll explore the cutting-edge materials revolutionizing sustainable labeling, examine the quantifiable business benefits that early adopters are experiencing, and provide a practical framework for selecting options that align with your specific operational needs and environmental goals.

The reality is that today’s eco-friendly stickers not only match conventional alternatives in performance and aesthetics—they often exceed them while delivering additional benefits that extend far beyond environmental impact. From enhanced brand perception to improved regulatory compliance positioning, sustainable stickers represent a convergence of environmental responsibility and smart business strategy.

Whether you’re taking your first steps toward sustainable packaging or looking to optimize an existing eco-friendly initiative, this guide will serve as your definitive resource for understanding, evaluating, and implementing eco-friendly sticker solutions that maintain the performance standards Australian businesses demand.

The term “eco-friendly stickers” encompasses far more than simply using recycled paper or plant-based materials. True sustainability in sticker manufacturing represents a holistic approach that considers every aspect of the product lifecycle, from raw material sourcing through end-of-life disposal. Understanding these fundamentals is crucial for making informed decisions that align with both your environmental goals and operational requirements.

At its core, an eco-friendly sticker differs from conventional alternatives through three fundamental characteristics: the use of renewable or recycled base materials, the incorporation of biodegradable or compostable components, and adherence to responsible manufacturing processes that minimize environmental impact throughout production. These characteristics work together to create products that perform as expected while significantly reducing their environmental footprint compared to traditional petroleum-based alternatives.

The three pillars of sustainable stickers form the foundation for evaluating any eco-friendly option. Renewable materials include plant-based films derived from corn starch, cellulose, or agricultural waste, as well as papers made from rapidly renewable resources like bamboo or hemp. These materials offer the dual benefit of reducing dependence on finite fossil fuel resources while often providing superior biodegradability at end-of-life.

Biodegradable components extend beyond the face material to include adhesives, release liners, and inks that break down naturally without leaving harmful residues. This comprehensive approach ensures that every component of the sticker contributes to its overall sustainability profile rather than creating a mixed-material challenge for disposal systems.

Responsible manufacturing encompasses energy-efficient production processes, waste reduction initiatives, water conservation measures, and the use of renewable energy sources where possible. These practices often result in products that not only reduce environmental impact but also demonstrate superior consistency and quality control due to the precise monitoring required for sustainable certification.

Environmental certifications provide crucial third-party validation of sustainability claims, helping businesses navigate the complex landscape of eco-friendly options. The Forest Stewardship Council (FSC) certification guarantees that paper-based materials come from responsibly managed forests that provide environmental, social, and economic benefits. This certification is particularly valuable for businesses seeking to demonstrate clear supply chain sustainability to stakeholders and customers.

The EN 13432 standard provides rigorous testing criteria for compostability, ensuring that materials will break down completely under industrial composting conditions within specified timeframes. Products meeting this standard can be confidently integrated into existing waste management systems without creating contamination concerns or processing complications.

OK Compost certification takes sustainability a step further by validating home compostability, enabling end-users to dispose of stickers in backyard compost systems. This certification is particularly valuable for consumer-facing products where end-of-life disposal responsibility lies with individual households rather than commercial waste management systems.

Common myths about eco-friendly stickers often center on concerns about durability, appearance, and cost that reflect outdated experiences with early sustainable products. Modern eco-friendly stickers match or exceed conventional alternatives in weather resistance, adhesion strength, and color vibrancy while offering additional benefits like improved printability and enhanced tactile qualities that many customers find appealing.

The lifecycle approach to sustainability assessment considers environmental impact from raw material extraction through manufacturing, transportation, use, and end-of-life disposal. This comprehensive perspective reveals that eco-friendly stickers often deliver lower total environmental impact even when initial production energy requirements are higher, due to their renewable material base and improved end-of-life characteristics.

Primary sustainable material categories include recycled content options that divert waste from landfills while reducing demand for virgin materials, plant-based alternatives that utilize renewable resources and often provide enhanced biodegradability, and biodegradable options specifically designed for optimal composting performance. Each category offers distinct advantages depending on application requirements and sustainability priorities.

Understanding these fundamentals provides the knowledge base necessary for evaluating specific applications and material options. The intersection of environmental benefit and practical performance creates opportunities for businesses to enhance their sustainability profile while often achieving superior results compared to conventional alternatives. This foundation sets the stage for exploring why these characteristics translate into tangible business value and environmental impact reduction.

The decision to adopt eco-friendly stickers represents far more than an environmental gesture—it’s a strategic business investment that delivers measurable returns across multiple operational and marketing dimensions. Understanding these benefits helps frame sustainability initiatives within broader business objectives while providing the data needed to secure stakeholder buy-in and budget approval for eco-friendly transitions.

Environmental impact reduction forms the foundation of eco-friendly sticker benefits, but the quantifiable nature of these improvements makes them valuable for corporate reporting and stakeholder communication. Carbon footprint reduction through renewable material use and energy-efficient manufacturing typically ranges from 30-60% compared to conventional petroleum-based alternatives, depending on material choices and transportation factors. This reduction directly supports corporate sustainability goals while providing concrete data for ESG reporting and customer communication.

Waste reduction benefits extend beyond the stickers themselves to encompass packaging optimization and supply chain efficiencies. Many eco-friendly options offer enhanced recyclability or compostability that simplifies waste management for both businesses and end-users, reducing disposal costs and complexity while supporting circular economy initiatives. Resource conservation through renewable material use reduces dependence on finite petroleum resources while supporting agricultural communities and sustainable land use practices.

The business benefits of eco-friendly sticker adoption create compelling value propositions that often surprise decision-makers focused primarily on cost considerations. Enhanced brand reputation represents one of the most significant advantages, as research shows that eco-friendly packaging strengthens brand perception and increases customer loyalty, particularly among younger demographics who increasingly make purchasing decisions based on environmental considerations.

Customer loyalty increases manifest in both direct sales growth and reduced customer acquisition costs, as satisfied customers become brand advocates who generate organic marketing through word-of-mouth recommendations and social media engagement. This loyalty premium often translates into reduced price sensitivity and increased lifetime customer value, creating sustainable competitive advantages that compound over time.

Competitive differentiation through sustainable packaging choices becomes increasingly valuable as environmental consciousness spreads across consumer segments and B2B procurement processes. Early adopters often capture disproportionate attention and market share as customers seek alternatives to conventional suppliers, creating first-mover advantages that persist even as sustainable options become more widely available.

Financial returns data shows that 85% of businesses achieve positive ROI within 6 months of implementing sustainable sticker solutions, primarily through increased customer retention, premium pricing opportunities, and operational efficiencies. These rapid returns reflect both the immediate marketing benefits of sustainable positioning and the long-term value of building environmentally conscious customer relationships.

Consumer perception improvements create opportunities for premium pricing that often offset any initial cost increases associated with eco-friendly materials. Customers frequently express willingness to pay 10-15% premiums for demonstrably sustainable products, while business customers increasingly weight environmental considerations in their vendor selection processes. This pricing flexibility provides businesses with multiple pathways to profitability while advancing environmental goals.

Regulatory compliance advantages position businesses ahead of evolving environmental legislation that increasingly targets packaging waste and single-use plastics. Australia’s growing focus on Extended Producer Responsibility (EPR) schemes and plastic waste reduction creates regulatory risks for businesses relying heavily on conventional packaging materials, while sustainable alternatives provide compliance insurance that protects against future regulatory changes.

Supply chain sustainability improvements often emerge as unexpected benefits of eco-friendly sticker adoption, as sustainable material suppliers typically demonstrate superior transparency, quality control, and innovation capacity compared to conventional suppliers. These partnerships often lead to broader sustainability improvements throughout packaging and operational processes, creating synergistic benefits that extend far beyond sticker applications.

Corporate Social Responsibility (CSR) and ESG reporting benefits provide valuable content for sustainability communications while supporting broader corporate initiatives around environmental stewardship and stakeholder engagement. Quantifiable sustainability metrics from sticker choices contribute to comprehensive ESG portfolios that increasingly influence investment decisions, insurance rates, and partnership opportunities.

The cumulative effect of these benefits creates business cases that often exceed initial expectations, particularly when implemented as part of broader sustainability strategies. Companies report that eco-friendly sticker adoption frequently serves as a gateway to larger sustainability initiatives, building internal capabilities and stakeholder confidence that enable more ambitious environmental projects.

The intersection of environmental responsibility and business performance creates sustainable competitive advantages that strengthen over time as environmental consciousness continues growing across consumer and business markets. Understanding these benefits provides the foundation for exploring the specific materials that deliver these advantages while meeting diverse application requirements and performance standards.

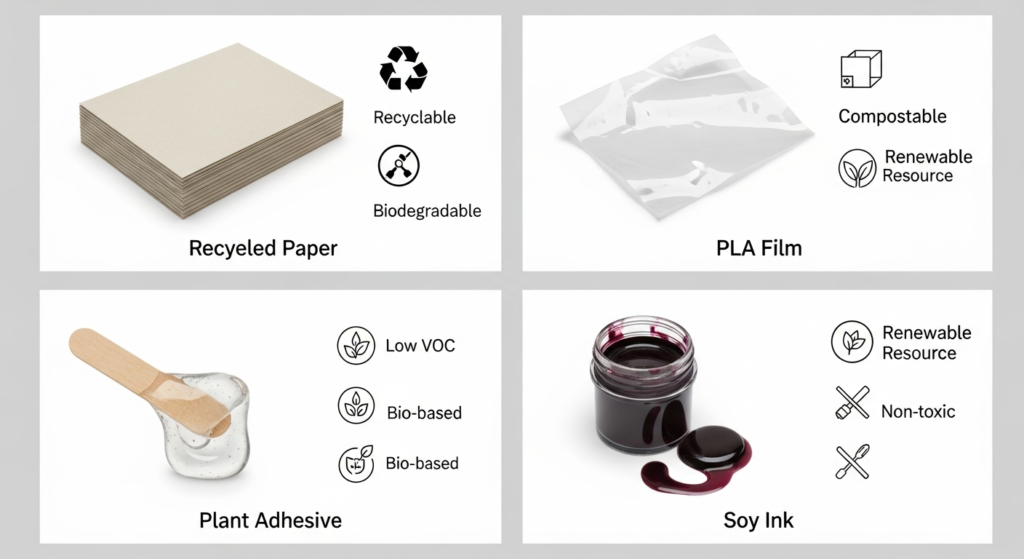

The materials science revolution behind eco-friendly stickers represents one of the most significant advances in sustainable packaging technology, combining innovative chemistry with traditional manufacturing expertise to create products that often outperform conventional alternatives. Understanding these materials and their properties enables informed selection decisions that optimize both environmental impact and practical performance for specific applications.

Recycled paper options have evolved far beyond basic kraft papers to include sophisticated alternatives that match premium conventional materials in appearance and functionality. 100% post-consumer content papers utilize waste paper streams that would otherwise require landfill disposal, providing closed-loop recycling benefits while delivering excellent printability and adhesion characteristics. These materials often demonstrate superior dimensional stability compared to virgin papers, as the recycling process tends to align fiber structure more consistently.

Agricultural waste papers represent an particularly innovative category, utilizing materials like sugarcane bagasse, wheat straw, and rice hulls that traditionally required disposal or burning. These alternatives provide dual environmental benefits by reducing agricultural waste while creating valuable paper products, often with unique aesthetic qualities that enhance product differentiation. The natural variations in fiber color and texture create distinctive appearances that many brands find appealing for organic or artisanal positioning.

Tree-free alternatives extend beyond agricultural waste to include rapidly renewable resources like bamboo, hemp, and kenaf that can be harvested sustainably without depleting forest resources. These materials often provide enhanced durability and water resistance compared to traditional wood-based papers, making them particularly suitable for outdoor applications or products requiring extended shelf life.

Plant-based films represent the cutting edge of sustainable sticker technology, offering transparency, durability, and versatility that rivals or exceeds petroleum-based alternatives. Polylactic acid (PLA) films derived from corn starch provide excellent clarity and printability while maintaining compostability under industrial conditions. Research indicates that PLA-based stickers can reduce carbon footprint by up to 50% compared to conventional vinyl alternatives, making them attractive for businesses seeking measurable environmental improvements.

Cellulose films manufactured from sustainably sourced wood pulp offer exceptional moisture resistance and conformability, making them ideal for curved surfaces and humid environments. These films often demonstrate superior aging characteristics compared to plastic alternatives, maintaining clarity and adhesion performance over extended periods while remaining fully biodegradable at end-of-life.

Hemp-based materials provide exceptional durability and natural antimicrobial properties that extend product life while reducing preservation requirements. The rapid growth cycle and minimal environmental impact of hemp cultivation make these materials particularly attractive for businesses seeking to minimize agricultural footprint while maximizing material performance.

Biodegradable adhesives represent a critical but often overlooked component of sustainable sticker design, as conventional petroleum-based adhesives can compromise the compostability of otherwise sustainable materials. Water-based formulations eliminate volatile organic compounds (VOCs) while providing excellent initial tack and long-term adhesion performance across diverse substrate types. These adhesives often demonstrate improved aging characteristics, maintaining bond strength longer than solvent-based alternatives while avoiding the environmental and health concerns associated with chemical solvents.

Advanced water-based adhesive technologies incorporate renewable tackifiers derived from plant resins, creating fully bio-based adhesive systems that complement sustainable face materials and release liners. These formulations often provide enhanced removability characteristics, reducing residue concerns while maintaining strong initial bonds that meet demanding application requirements.

Sustainable ink technologies complete the eco-friendly sticker ecosystem by providing vibrant colors and sharp detail while minimizing environmental impact throughout the printing process. Soy-based inks derived from renewable soybean oil provide excellent color saturation and rub resistance while eliminating petroleum-based solvents and reducing VOC emissions during printing. These inks often demonstrate superior fade resistance compared to conventional alternatives, maintaining color integrity longer under UV exposure and temperature variations.

Water-based ink systems eliminate solvent emissions entirely while providing excellent print quality and adhesion to diverse substrate materials. Advanced water-based formulations incorporate nano-pigment technologies that deliver exceptional color density and weather resistance while maintaining full biodegradability and compostability.

UV-LED curable formulations represent the newest advancement in sustainable printing technology, providing instant curing with minimal energy consumption while eliminating mercury and ozone concerns associated with traditional UV systems. These inks often provide enhanced durability and chemical resistance while maintaining compatibility with recycling and composting systems.

Durability and performance characteristics of sustainable materials often surprise businesses accustomed to conventional alternatives. Modern eco-friendly stickers frequently exceed conventional materials in UV resistance, temperature stability, and moisture resistance while providing equivalent or superior printability and adhesion performance. The key lies in matching material properties to application requirements rather than assuming universal superiority of any single material type.

Cost implications vary significantly depending on material choices, order volumes, and performance requirements, but the gap between sustainable and conventional options continues narrowing as sustainable production scales increase and petroleum costs fluctuate. Many businesses discover that total cost of ownership, including disposal costs and customer acquisition benefits, often favors sustainable alternatives even when initial material costs are higher.

Material availability considerations reflect the rapid growth of sustainable material production capacity, with most options now readily available for standard applications while specialty requirements may require longer lead times or minimum order quantities. Working with experienced suppliers helps navigate availability constraints while identifying opportunities for custom material development when standard options don’t meet specific requirements.

Application-specific material recommendations depend on environmental exposure, substrate requirements, and end-of-life considerations, with indoor applications typically offering broader material choices while outdoor or food-contact applications require more specialized formulations that balance performance with sustainability goals.

The continuing evolution of sustainable materials technology promises even more sophisticated options in the near future, with developments in bio-based polymers, agricultural waste utilization, and closed-loop recycling systems creating new possibilities for high-performance sustainable stickers. Understanding current options provides the foundation for making informed decisions while staying positioned to adopt emerging technologies as they become commercially viable.

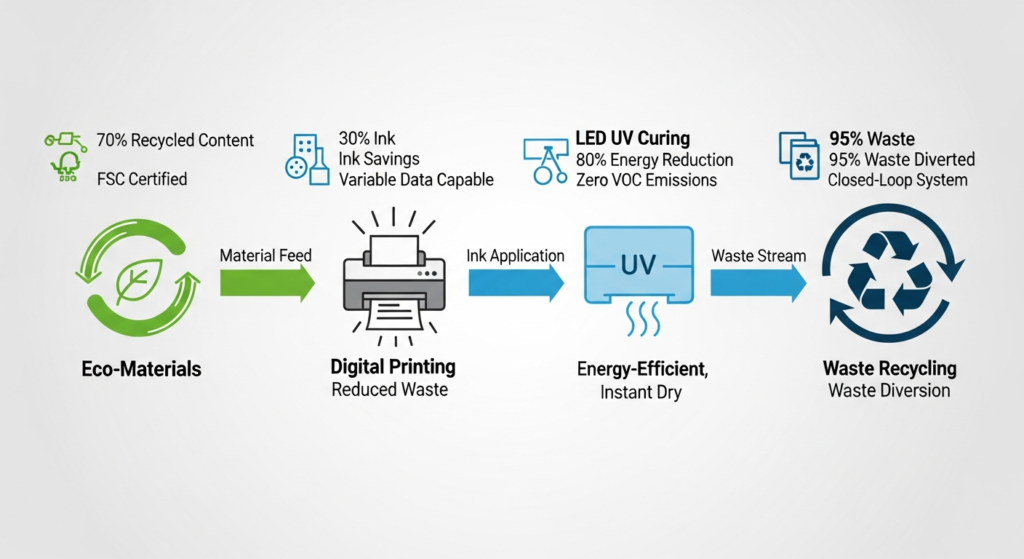

The manufacturing processes behind eco-friendly stickers represent a fundamental shift from traditional production approaches, integrating environmental considerations into every aspect of the production workflow while often achieving superior quality and consistency compared to conventional methods. Understanding these processes helps businesses appreciate the complete sustainability profile of eco-friendly options while identifying manufacturing partners who can deliver both environmental performance and operational reliability.

Digital printing technology has revolutionized sustainable sticker production by enabling on-demand manufacturing that eliminates setup waste, reduces inventory requirements, and provides unprecedented flexibility for customization and short runs. Unlike traditional analog printing processes that require extensive setup materials and generate significant waste during color matching and registration, on-demand digital production prints only the exact quantities needed, when needed, reducing material waste by up to 90% compared to conventional offset printing for small to medium runs.

Reduced setup waste extends beyond immediate material savings to encompass the elimination of cleaning solvents, setup sheets, and color proofing materials traditionally required for conventional printing. Digital processes typically achieve color accuracy within one to two test prints rather than the dozens often required for analog processes, significantly reducing both material consumption and production time while improving overall efficiency.

Energy efficiency improvements in digital printing systems often reduce power consumption by 40-60% compared to conventional printing equipment, particularly when utilizing LED-UV curing systems that eliminate the heat and energy requirements of traditional mercury-vapor UV systems. These efficiency gains translate directly into reduced carbon footprint while often providing superior curing consistency that improves product quality and durability.

Sustainable ink systems represent another critical component of environmentally responsible manufacturing, with water-based and bio-based formulations eliminating the volatile organic compound (VOC) emissions that traditional solvent-based inks release during printing and drying. Water-based printing systems not only eliminate harmful emissions but often provide superior print quality through improved dot gain control and color consistency, while bio-based ink formulations derived from renewable resources like soy oil or vegetable oils provide excellent color saturation and rub resistance without petroleum-based components.

The VOC emission reductions achieved through sustainable ink systems often exceed 95% compared to conventional solvent-based processes, creating healthier work environments while reducing environmental impact. These improvements frequently enable manufacturing facilities to operate without expensive air pollution control equipment while meeting or exceeding environmental regulations that continue tightening globally.

Energy-efficient technologies extend throughout the sustainable manufacturing ecosystem, with LED UV curing systems providing instant curing with 80% less energy consumption compared to traditional mercury-vapor systems while eliminating mercury disposal concerns and reducing heat generation that can damage sensitive materials. The instant-on capability of LED systems eliminates warm-up waste while providing consistent curing intensity throughout long production runs.

Solar-powered facilities represent the leading edge of sustainable manufacturing, with many eco-friendly sticker producers investing in renewable energy systems that reduce or eliminate grid electricity consumption while providing long-term energy cost stability. These investments often create additional value through renewable energy certificate programs and carbon offset opportunities that enhance overall sustainability profiles.

Waste heat recovery systems capture and repurpose thermal energy generated during printing and curing processes, reducing overall energy consumption while often improving production environment climate control. These systems typically achieve 15-25% additional energy efficiency improvements while reducing HVAC loads and improving worker comfort.

Waste reduction strategies in sustainable manufacturing encompass both material optimization and process innovation designed to minimize waste generation at every production stage. Linerless label technologies eliminate the release liner entirely, reducing material consumption by approximately 40% while often providing enhanced application efficiency and reduced disposal requirements for end-users.

Optimized cutting processes utilize advanced nesting algorithms and precision cutting technologies to maximize material utilization, often achieving 95%+ yield rates that significantly exceed conventional cutting methods. These improvements reduce both material costs and waste disposal requirements while often enabling smaller minimum orders that support just-in-time inventory strategies.

Material recapture systems collect and reprocess production waste back into usable materials, creating closed-loop manufacturing processes that eliminate waste disposal while reducing raw material requirements. These systems often process edge trim, setup waste, and off-specification materials into recycled content for future production runs, contributing to circular economy objectives while reducing costs.

Water conservation represents another critical aspect of sustainable manufacturing, with closed-loop water systems recycling process water through filtration and treatment systems that eliminate discharge requirements while reducing consumption by up to 80%. Chemical waste minimization through advanced ink formulations and cleaning processes reduces hazardous waste generation while often improving workplace safety and regulatory compliance.

Local manufacturing provides significant sustainability advantages through reduced transportation emissions, improved quality control, and enhanced supply chain resilience. Reduced transportation emissions often account for 10-20% of total product carbon footprint, making local sourcing a valuable sustainability strategy while providing additional benefits like shortened lead times and improved communication with production partners.

Quality control improvements through local manufacturing enable more frequent inspections, faster problem resolution, and better customization capabilities while reducing the quality risks associated with long-distance shipping and communication challenges. These advantages often result in higher customer satisfaction and reduced waste from quality issues.

Certification requirements for sustainable printing facilities provide third-party validation of environmental claims while ensuring consistent performance across production runs and suppliers. Sustainable printing certifications typically encompass energy efficiency, waste reduction, chemical management, and worker safety standards that create comprehensive frameworks for environmental responsibility.

LED UV technology benefits extend beyond energy efficiency to include improved print quality through more consistent curing, reduced substrate heating that prevents material distortion, and elimination of ozone generation that requires ventilation systems. These technical advantages often result in superior product performance while reducing environmental impact.

Digital printing sustainability encompasses not only waste reduction but also improved inventory efficiency, reduced obsolescence risk, and enhanced customization capabilities that enable more targeted marketing approaches and reduced overproduction. These benefits create value throughout the supply chain while supporting environmental objectives.

The convergence of environmental responsibility and manufacturing excellence in sustainable sticker production demonstrates that sustainability often drives innovation that improves quality, efficiency, and cost-effectiveness while reducing environmental impact. Understanding these processes provides the foundation for evaluating manufacturing partners and making informed decisions about sustainable sticker options that meet both performance and environmental objectives.

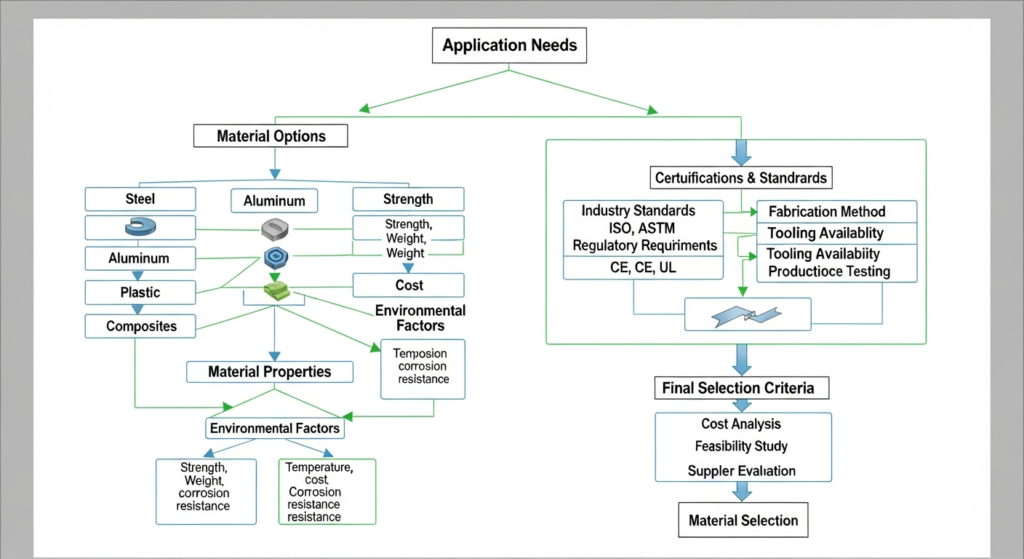

Selecting the right eco-friendly stickers requires a systematic approach that balances environmental objectives with practical performance requirements, cost considerations, and operational constraints. A well-structured decision framework helps businesses navigate the expanding array of sustainable options while ensuring that chosen solutions deliver both environmental benefits and operational success.

Application requirements assessment forms the foundation of effective eco-friendly sticker selection, beginning with a comprehensive evaluation of performance demands that will determine material compatibility and certification needs. Durability requirements vary dramatically between indoor applications that need only basic moisture resistance and outdoor applications requiring UV stability, temperature cycling resistance, and extended weather exposure performance. Understanding these requirements prevents both over-specification that increases costs unnecessarily and under-specification that leads to product failures and customer satisfaction issues.

Environmental exposure analysis should consider not only direct weather conditions but also temperature extremes, humidity variations, chemical exposure risks, and UV intensity that may affect material performance over time. Many eco-friendly materials actually provide superior performance in challenging environments due to their enhanced UV resistance and moisture stability, making them particularly attractive for demanding applications.

Adhesion requirements encompass both initial bond strength and long-term performance across diverse substrate materials, with consideration for removal requirements if repositioning or temporary applications are needed. Sustainable adhesive technologies often provide enhanced removability characteristics while maintaining strong initial bonds, creating opportunities for applications where conventional adhesives might cause substrate damage during removal.

Certification evaluation represents a critical component of eco-friendly sticker selection, with different certification types providing varying levels of environmental assurance and third-party validation. Type I environmental labels provide the highest level of credibility through independent third-party verification of environmental claims against established criteria, making them particularly valuable for businesses seeking to communicate sustainability credentials to environmentally conscious customers and stakeholders.

Type II self-declared environmental claims offer flexibility and cost advantages but require careful evaluation to ensure accuracy and avoid greenwashing concerns that could damage brand credibility. These claims can be valuable when supported by transparent documentation and clear performance data, but businesses should verify claims independently when possible.

Type III environmental product declarations (EPDs) provide comprehensive lifecycle assessment data that enables detailed comparison between alternatives and supports sophisticated environmental decision-making. While more complex to interpret, EPDs offer the most complete picture of environmental impact and are increasingly required for institutional and government procurement processes.

Material selection criteria must balance performance requirements with sustainability objectives and cost constraints, recognizing that optimal solutions often involve trade-offs between different environmental and practical considerations. Performance requirements should be clearly defined and prioritized, with essential characteristics distinguished from preferences that might be compromised for environmental or cost benefits.

End-of-life options vary significantly between materials and applications, with home compostable options providing maximum convenience for consumer applications while industrial compostable alternatives may be more appropriate for business-to-business applications where waste management systems can handle specialized disposal requirements. Recyclable options often provide the best balance for applications where composting infrastructure is limited but recycling systems are well-established.

Cost considerations should encompass total cost of ownership including disposal costs, potential premium pricing opportunities, and customer acquisition benefits rather than focusing solely on material costs. Many businesses discover that sustainable options provide positive returns through enhanced customer loyalty and brand differentiation even when initial costs are higher.

Supplier evaluation requires comprehensive assessment of capabilities, transparency, and commitment to sustainable practices throughout their operations. Transparency in supply chain documentation indicates suppliers who understand and control their environmental impact while providing the traceability information increasingly required for sustainability reporting and customer communication.

Manufacturing practice verification should encompass energy efficiency, waste reduction, worker safety, and environmental compliance while evaluating capacity for innovation and continuous improvement. Leading sustainable suppliers typically demonstrate superior quality control and customer service due to the attention to detail required for environmental certification maintenance.

Traceability capabilities enable comprehensive lifecycle assessment and support chain-of-custody requirements for certified materials, while providing the documentation needed for sustainability reporting and customer communication. Suppliers with robust traceability systems typically provide more reliable delivery performance and quality consistency.

Avoiding greenwashing requires careful evaluation of environmental claims against objective criteria and third-party verification, with particular attention to vague or unsubstantiated claims that may be designed more for marketing appeal than environmental performance. Red flag indicators include claims lacking specific data, certifications from unknown organizations, or environmental benefits that seem inconsistent with material properties or manufacturing processes.

Verification methods include requesting documentation of environmental claims, checking certification validity through certifying organization databases, and comparing claims across multiple suppliers to identify inconsistencies or exaggerations. Understanding environmental label fundamentals helps businesses navigate complex certification landscapes while making informed decisions.

Cost-benefit analysis frameworks should incorporate both quantifiable financial factors and qualitative benefits that may be difficult to measure but provide significant value over time. Initial investment considerations include material cost premiums, potential tooling or process changes, and training requirements balanced against operational savings, customer acquisition benefits, and risk reduction value.

Long-term return calculations should include customer loyalty improvements, brand value enhancement, regulatory compliance benefits, and potential premium pricing opportunities while considering the risk of future regulatory changes that might penalize conventional materials. Sustainable packaging frameworks provide structured approaches for comprehensive evaluation.

Minimum order considerations and testing recommendations help businesses manage transition risks while optimizing investment efficiency. Sample testing programs enable performance validation under actual application conditions while providing customer feedback opportunities before committing to large quantities. Pilot program strategies allow gradual implementation that builds internal capabilities while demonstrating results to stakeholders.

The systematic application of these selection criteria ensures that eco-friendly sticker choices deliver both environmental benefits and operational success while positioning businesses for continued success as sustainability requirements continue evolving. Common myths about eco-friendly labels often stem from inadequate evaluation processes that focus on individual factors rather than comprehensive assessment of value and performance.

Understanding this framework provides the foundation for successful implementation strategies that maximize both environmental impact and business value while minimizing transition risks and operational disruptions.

Successfully implementing eco-friendly sticker solutions requires careful planning, stakeholder engagement, and systematic execution that minimizes disruption while maximizing both environmental and business benefits. A structured implementation approach helps businesses navigate common challenges while building capabilities that support continued sustainability advancement across their operations.

Implementation timeline recommendations should balance the desire for rapid environmental impact with practical considerations around inventory management, stakeholder education, and performance validation. Testing phases typically require 4-6 weeks for comprehensive evaluation under actual application conditions, including adhesion performance, durability assessment, and customer feedback collection. This testing period proves critical for identifying potential issues before full-scale implementation while building internal confidence in sustainable alternatives.

Gradual rollout strategies often provide optimal balance between implementation speed and risk management, beginning with less critical applications or smaller product lines where performance issues would have limited impact. This approach enables learning and process refinement while demonstrating success that builds stakeholder support for broader implementation across more critical applications.

Full conversion timelines typically span 6-12 months for comprehensive transitions, depending on inventory levels, supplier relationships, and application complexity. Planning for longer timelines often results in smoother implementations with fewer disruptions, while aggressive timelines risk quality issues and stakeholder resistance that can compromise long-term success.

Stakeholder communication represents a critical success factor that requires tailored messaging for different audiences while maintaining consistency around sustainability objectives and business benefits. Customer education programs should emphasize performance equivalence while highlighting environmental benefits, addressing potential concerns about change while building excitement around sustainability leadership.

Effective customer communication often includes sample programs that allow customers to experience sustainable alternatives firsthand while providing educational materials that explain environmental benefits and disposal instructions. Many businesses discover that customers appreciate transparency about sustainability initiatives and often become advocates who promote environmental responsibility to their own stakeholders.

Internal team training should encompass both technical aspects of new materials and processes as well as sustainability messaging that enables employees to communicate effectively with customers and stakeholders. Training programs often reveal employee enthusiasm for sustainability initiatives while building capabilities that support broader environmental objectives.

Supplier coordination requires clear communication about quality expectations, delivery requirements, and performance standards while establishing feedback mechanisms that enable continuous improvement. Strong supplier relationships often lead to preferential access to new sustainable technologies and materials while providing technical support that accelerates implementation success.

Performance monitoring and success metrics provide crucial feedback for optimization while supporting sustainability reporting and stakeholder communication. Environmental impact tracking should include quantifiable metrics like carbon footprint reduction, waste diversion, and renewable content percentages that demonstrate progress toward sustainability goals while providing content for marketing and reporting purposes.

Customer satisfaction monitoring ensures that sustainable alternatives maintain or improve customer experience while identifying opportunities for further optimization. Many businesses discover that customers prefer sustainable alternatives once they experience comparable or superior performance, leading to enhanced loyalty and word-of-mouth promotion.

Operational efficiency metrics often reveal unexpected benefits from sustainable implementation, including reduced inventory complexity, improved supplier relationships, and enhanced employee engagement that contribute to overall business performance beyond environmental impact.

Common implementation challenges typically involve coordination between multiple stakeholders, adaptation to new processes, and management of transition timing to minimize disruption. Inventory management challenges can be addressed through careful planning that coordinates existing stock depletion with sustainable alternative availability while avoiding stockouts that could disrupt customer service.

Process adaptation requirements often prove less significant than anticipated, particularly when working with experienced sustainable suppliers who provide technical support and process guidance. Many businesses discover that sustainable alternatives integrate seamlessly into existing workflows while sometimes providing enhanced efficiency through improved material properties.

Quality consistency concerns can be addressed through robust testing programs and close supplier relationships that ensure consistent performance across production runs while building confidence in sustainable alternatives among quality control and customer service teams.

Future industry trends position early adopters for continued competitive advantages while providing insights into emerging opportunities and potential challenges. Innovative material development continues advancing sustainable options that provide enhanced performance while reducing environmental impact, with developments in bio-based polymers, agricultural waste utilization, and closed-loop recycling creating new possibilities for high-performance sustainable stickers.

Regulatory evolution increasingly favors sustainable alternatives through Extended Producer Responsibility schemes, plastic waste reduction mandates, and carbon pricing mechanisms that improve the competitive position of eco-friendly options while creating compliance risks for businesses relying on conventional materials.

Market growth projections indicate accelerating adoption of sustainable packaging across all sectors, with market trends showing increasing consumer awareness and regulatory pressure driving demand for verified sustainable alternatives. Early adopters often capture disproportionate market share as sustainability becomes a competitive differentiator.

Emerging technologies promise even more sophisticated sustainable solutions in the near future, with smart sustainable labels incorporating digital functionality while maintaining environmental benefits, blockchain traceability systems providing comprehensive supply chain transparency, and closed-loop recycling systems enabling circular economy approaches that eliminate waste entirely.

Future label innovations include developments in bio-based electronics, agricultural waste utilization, and advanced recycling technologies that create new possibilities for sustainable labeling while often providing enhanced functionality compared to conventional alternatives.

Australia-specific considerations reflect local regulatory developments, supplier networks, and climate factors that influence material selection and implementation strategies. Local regulations around packaging waste and carbon emissions increasingly favor sustainable alternatives while creating compliance advantages for businesses that implement eco-friendly solutions proactively.

Supplier network development within Australia provides access to regional expertise and reduced transportation emissions while supporting local economic development and supply chain resilience. Many Australian sustainable suppliers offer specialized knowledge of local conditions and requirements while providing personalized service that enhances implementation success.

Climate factor considerations including UV intensity, temperature extremes, and humidity variations often favor sustainable materials that demonstrate superior weather resistance and aging characteristics compared to conventional alternatives, making eco-friendly stickers particularly attractive for Australian conditions.

Implementation best practices emphasize systematic approaches that balance environmental objectives with practical constraints while building capabilities that support continued sustainability advancement throughout business operations.

The systematic approach to eco-friendly sticker implementation creates sustainable competitive advantages while advancing environmental objectives that align with growing stakeholder expectations and regulatory requirements. Success in implementation provides the foundation for broader sustainability initiatives while demonstrating that environmental responsibility enhances rather than compromises business performance.

The journey through eco-friendly sticker options reveals a landscape rich with opportunities for Australian businesses to enhance their environmental profile while achieving superior operational results. Far from the compromised performance that many still associate with sustainable alternatives, today’s eco-friendly stickers represent the convergence of environmental responsibility and business excellence, offering solutions that frequently exceed conventional alternatives in durability, appearance, and customer appeal.

The business case for eco-friendly stickers extends well beyond environmental stewardship to encompass quantifiable benefits including enhanced brand reputation, increased customer loyalty, premium pricing opportunities, and competitive differentiation that compounds over time. With 85% of businesses achieving positive ROI within six months of implementation, the financial argument for sustainable stickers aligns perfectly with environmental objectives, creating win-win scenarios that benefit both business performance and environmental protection.

The materials science revolution behind modern eco-friendly stickers has eliminated the performance trade-offs that once made sustainable options less attractive than conventional alternatives. From recycled papers that exceed virgin materials in consistency to plant-based films that provide superior weather resistance, sustainable materials often deliver enhanced functionality while dramatically reducing environmental impact throughout their lifecycle.

Manufacturing innovations in digital printing, LED-UV curing, and closed-loop production processes demonstrate that environmental responsibility drives operational excellence rather than compromising it. Sustainable manufacturing often achieves superior quality control, reduced waste, and enhanced efficiency while eliminating harmful emissions and reducing energy consumption, creating value throughout the production process.

The strategic selection framework presented in this guide enables businesses to navigate the growing array of sustainable options with confidence, ensuring that chosen solutions deliver both environmental benefits and operational success. By systematically evaluating application requirements, certification standards, and supplier capabilities, businesses can make informed decisions that optimize both performance and sustainability while avoiding common pitfalls that might compromise results.

Implementation strategies that emphasize gradual transition, stakeholder engagement, and performance monitoring help businesses capture the full benefits of eco-friendly stickers while minimizing transition risks and operational disruptions. The systematic approach to implementation builds capabilities that support broader sustainability initiatives while demonstrating that environmental responsibility enhances rather than constrains business performance.

Looking forward, the continued evolution of sustainable materials technology, regulatory support for environmental alternatives, and growing consumer consciousness around sustainability create an increasingly favorable environment for eco-friendly sticker adoption. Early adopters position themselves to capture disproportionate benefits as sustainability becomes an increasingly important competitive differentiator across all market segments.

For Australian businesses, the combination of favorable climate conditions for sustainable materials, growing regulatory support for environmental alternatives, and increasing consumer awareness creates particularly compelling opportunities for sustainable sticker implementation. The alignment of environmental objectives with business performance creates sustainable competitive advantages that strengthen over time as environmental consciousness continues expanding across all market segments.

The choice to implement eco-friendly stickers represents more than a packaging decision—it’s a strategic investment in sustainable business practices that deliver both immediate returns and long-term competitive advantages. As environmental considerations become increasingly central to business success, sustainable sticker solutions provide accessible entry points for comprehensive sustainability initiatives that enhance brand value while advancing environmental objectives.

Ready to explore eco-friendly sticker options that maintain FastStickers.com.au’s signature lightning-fast turnaround while advancing your sustainability goals? Our experienced design team combines deep expertise in sustainable materials with proven production efficiency to deliver eco-friendly solutions that don’t compromise on quality or speed. Whether you need biodegradable labels for your product packaging, recycled paper stickers for your next promotional campaign, or plant-based films for demanding outdoor applications, we’ll help you find the perfect sustainable solution that enhances your brand while supporting your environmental objectives.

Contact FastStickers.com.au today for a free consultation and discover how our eco-friendly sticker options can strengthen your sustainability profile without sacrificing the rapid turnaround that keeps your business moving. Get your custom quote in minutes and join the growing community of Australian businesses making a positive environmental impact while maintaining the operational excellence that drives success. Your sustainable future starts with a single decision—make it today with FastStickers.com.au, where speed meets sustainability without compromise.

QR Code Stickers Australia: Smart Solutions for Business Growth In just three short years, Australia has witnessed a digital revolution that transformed how businesses interact

The Complete Guide to Candle Labels: Design, Materials & Australian Compliance Australia’s candle market is experiencing unprecedented growth, with handcrafted and artisanal candles driving a $200+

The Aussie Choice for a Greener Tomorrow Eco-friendly stickers are no longer a niche choice—they’re quickly becoming the go-to for Aussie businesses and event organisers

Choosing the Perfect Sticker Type for Your Project: A Quick Guide Picking the right sticker can make or break your project. Many get stuck choosing

Harnessing Gippsland’s Printing Expertise for Australian Business Success Most Australian businesses settle for slow, generic printing from big companies. You don’t have to. Gippsland printing